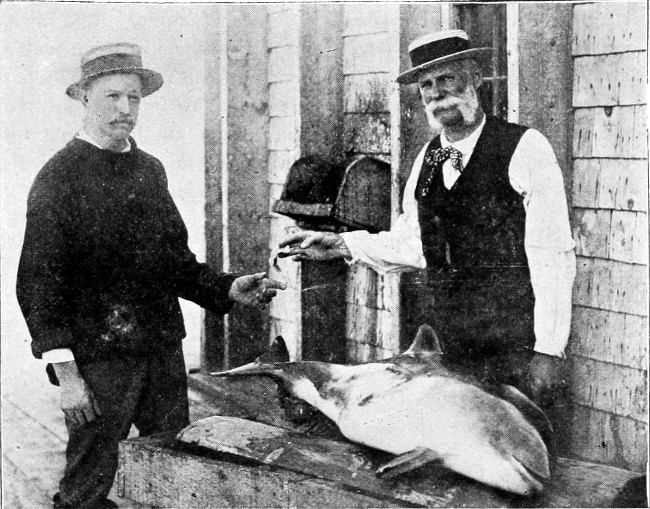

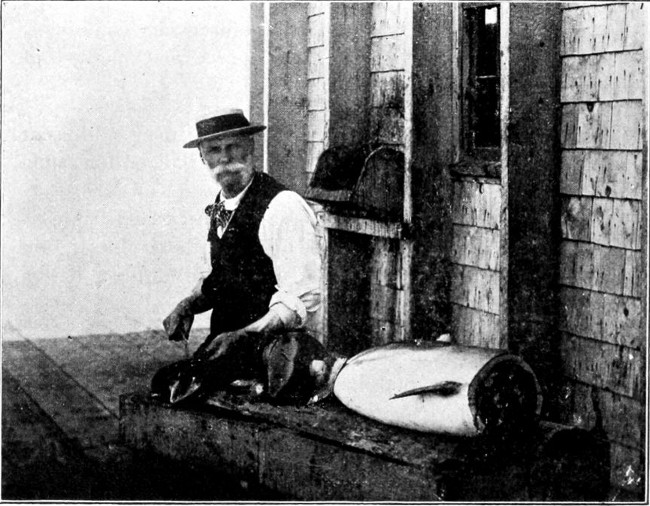

Fig. 1.—Buying a Porpoise from a Fisherman.

Fig. 1.—Buying a Porpoise from a Fisherman.

Title: Friction, Lubrication and the Lubricants in Horology

Author: W. T. Lewis

Release date: January 19, 2011 [eBook #35001]

Language: English

Credits: E-text prepared by the Online Distributed Proofreading Team (http://www.pgdp.net) from page images generously made available by Internet Archive/American Libraries (http://www.archive.org/details/americana)

| Note: | Images of the original pages are available through Internet Archive/American Libraries. See http://www.archive.org/details/frictionlubricat00lewi |

ILLUSTRATED WITH HALF-TONES AND

DRAWINGS BY THE AUTHOR.

CHICAGO:

GEO. K. HAZLITT & CO.

1896.

Copyrighted 1896, by W. T. Lewis.

Copyrighted 1896, by Geo. K. Hazlitt & Co.

Page.

Introduction, 7

CHAPTER I.

Lubricants in Horology—their Source and Methods of Refinement, 9

CHAPTER II.

Elementary Physics Relating to Friction and Lubrication, 21

CHAPTER III.

Friction—its Nature and Theory, 29

CHAPTER IV.

Application of the Laws of Friction and Lubrication in

Horology, 43

CHAPTER V.

The Properties and Relative Values of Lubricants in Horology, 61

Many books have been written on the various escapements, describing their action, construction and proportion, and the laws governing the same; learned writers have contributed much valuable information on adjusting; excellent attachments for the various lathes have been invented; and factories have expended fortunes to produce machinery of wonderful construction to finish all the parts of a watch in the most approved manner; but all this scientific research, all this painstaking effort, all this care and labor, are rendered abortive by the maker or repairer of a time piece if he does not thoroughly understand and apply the physical laws which govern the science of lubrication.

Many a watch, or chronometer, most excellent in all other respects, has come to an untimely end by an almost criminal neglect on the part of its maker to provide against wear in its various parts by such construction as would retain the oil at the places needed.

How often the repairer—clean he his work as well as he may—replace he the broken or worn part to put the time piece in as good condition as new—finds that its rate changes, that is loses time before long, and, at the end of one year[Pg 8] is badly out of repair, solely the result of lack of knowledge, or negligence, in properly lubricating, or on account of an oil having been used which was not suitable.

The object of this paper is to present in concise form the best of that which is furnished by the literature of the profession, together with that which has been written on friction and lubrication in general (so far as it may be applicable), by those not connected with this particular vocation; as well as the result of the practical experience of the manufacturers of time pieces in this country most of whom have furnished much useful data in answer to queries on the subject. The manufacturers of oils have also assisted by contributing valuable information.

The result of the author's experience, observation and experiments will also be incorporated; and he will be grateful to any who may read this work, who will call attention, through the trade papers, to any errors of omission or commission that they may find therein.

1. As but little is to be found on the subject in the literature accessible to most of the craft, a few remarks concerning the source and general methods of refining the oils used in horology will, no doubt, be of interest.

A mechanic who would work intelligently should possess a thorough knowledge of the materials constantly used, and oil is used on every horological mechanism. In order that this paper may be of maximum benefit and interest, the author has spared no pains in procuring useful data.

2. Porpoise Jaw Oil and Black Fish Melon Oil (64) have become widely known and justly celebrated in all parts of the world, as they were found to be better adapted for the purpose of lubricating fine and delicate machinery than any substance previously used.

3. Blackfish-Melon Oil[1] "derives its name from the mass taken from the top of the head of the animal reaching from the spout hole to the end of the nose, and from the top of the head down to the upper jaw, from which it is extracted. When taken off in one piece this mass represents a half watermelon, weighing about twenty-five pounds [Pg 10]ordinarily. When the knife is put into the center of this melon the oil runs out more freely than the water does from a very nice watermelon. Porpoise jaw oil and blackfish melon oil are worth from $5 to $15 per gallon, according to supply. They are not only used in horology, but by manufacturers of fine firearms, philosophical apparatus, and in government lighthouses for the clocks of revolving lights."

4. The Blubber, or fat, taken from the jaw of the porpoise or the head of the blackfish was formerly rendered in iron pots over a fire, but the modern method of extracting the oil by steam is said to be much superior. The oil is washed with water by thorough agitation, after which it is allowed to stand for several days, when it is drawn off and the last traces of water removed by distillation. The oil is then subjected to a very cold temperature and pressed through flannel cloths, by which process the "oleine" is separated from the "stearine," the resulting oil being more or less limpid as the former or latter constituent predominates.

5. John Wing, of New Bedford, Mass., son-in-law of, and successor to, the late Ezra Kelley, states in answer to inquiries, that their supply of oil comes from the porpoise and blackfish taken during the summer months on the coast of Africa, above the equator; and that they find that this oil contains less glutinous matter than that obtained in and about the St. Lawrence river, which fact he attributes to the difference in the food of the fish, which in turn affects the oil.

6. D. C. Stull, of Provincetown, Mass., in answer to inquiries on the subject, has kindly furnished the following information and series of views:[Pg 11]

Fig. 1.—Buying a Porpoise from a Fisherman.

Fig. 1.—Buying a Porpoise from a Fisherman.

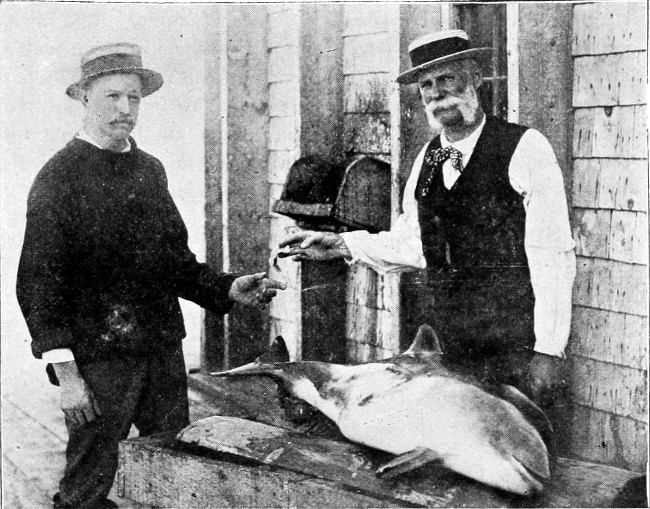

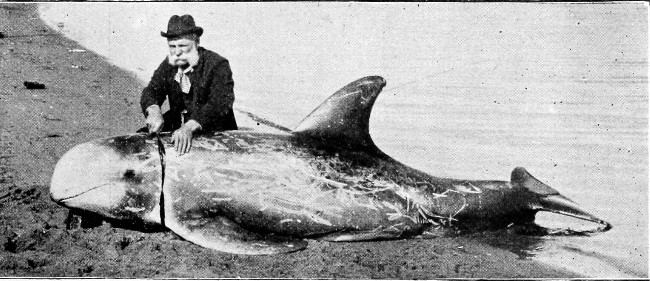

"The supply of porpoise-jaw oil and blackfish-melon oil comes mostly from Massachusetts Bay, the trap and gill net fishermen bringing them into Provincetown, sometimes alive, as shown at Fig. 1. The capture of fifteen hundred blackfish, Fig. 2, by the people of Provincetown, Truro and Wellsfleet, was one of the most exciting scenes in the annals of coast fishery. The fish were attracted to these shores by the large quantity of squid and herring, on which they feed. It is estimated that the catch was worth $25,000,[Pg 12] some of the fish weighing two tons each. The relative size of a blackfish and a man is shown at Fig. 3. Seafaring men and whaling captains who catch the porpoise at sea, extract the oil from the head and jaw only, and bring it to the factories to be manufactured.

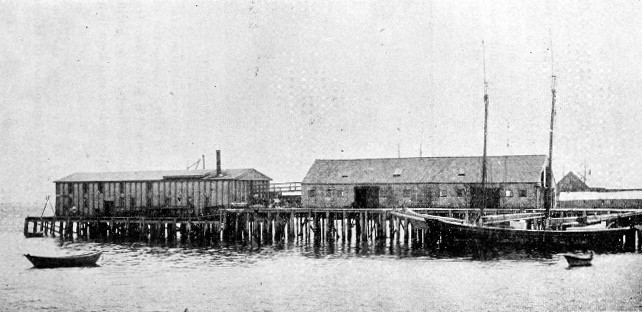

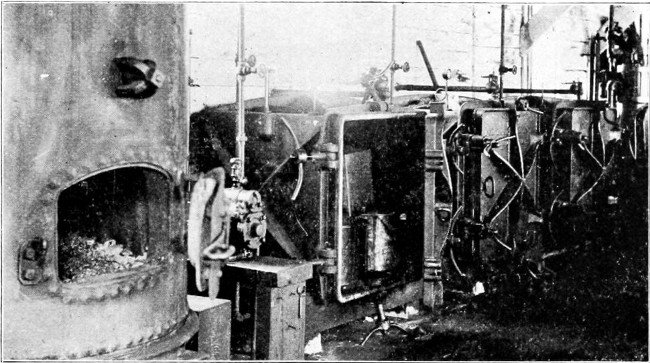

"Fig. 4 is a good view of a modern factory. The fat is cut from the head and jaw, (Fig. 5,) washed in fresh water and put into covered tin cans, then into iron retorts, (Fig. 6.) These retorts are then closed, screwed up tightly, and live steam turned on from the boiler. The fat is cooked by steam for five hours, with ten pounds pressure, at 230° F. By this means the crude oil is extracted from the fat."

7. Sperm Oil is the best known of all the lubricants and is, for general purposes, one of the most excellent.

The large cavity in the head of the sperm whale contains oil and solid fat, from which the former is separated, without heating, by pressure and crystalization. As it is not at present used to any great extent in horology, a more lengthy description of the method of refining will be omitted. (65.)

8. Bone Oil is made from the fat obtained by boiling the bones of animals. The finest quality is obtained from the leg bones of recently killed, healthy, young cattle, and the best method of treatment is given as follows[2]:

"Fill a bottle one third full of the oil to be purified. Then pour clarified benzine in small portions upon the oil, close the bottle and shake until the benzine has disappeared. By again adding benzine and shaking, a complete solution of the fat is finally effected. That this has actually taken place is[Pg 13] recognized by the contents of the bottle not separating after long standing. The bottle is then exposed to a low temperature for several hours, a solid fat deposits on the bottom, and the lower the temperature the greater is the deposit. Alongside the bottle containing the oil, place another bottle with a funnel, the lower end of which is closed by a cotton stopper; after thoroughly shaking the bottle with oil, pour the contents into the funnel; the fluid portion runs into the bottle, while the solid portion is retained in the funnel by the cotton stopper. The clear solution of bone oil in benzine collected in the bottle is then brought into a small retort which is connected with a thoroughly cooled receiver. Place the retort in a tin vessel filled with water and apply heat. The benzine readily distills off, leaving the purified bone oil in the retort." (66.)

9. Neat's-foot Oil is largely used in the arts, being one of the best of lubricants. The best oil, viz.: that used for clocks etc., is extracted by placing the thoroughly cleaned feet of cattle in a covered vessel near the fire or in the sun. The oil thus obtained is clarified by standing before bottling. (67.)

It was the practice of many olden time watchmakers to allow a large bottle of neat's-foot oil to stand in a position exposed to the direct rays of the sun in summer and to the extreme cold of the winter. Then after two or three years, on a very cold winter day, to pour off such oil as still remained fluid which was preserved for use.

10. Olive Oil has been used as a lubricant since the early days of horology, the older writers giving many [Pg 14]methods of treating it. It is obtained from the fruit of the Olea Europea, one of the jasmines, which grows throughout Southern Europe and Northern Africa and other tropical countries.

Fig. 2.—A $25,000 Catch of Blackfish.

Fig. 2.—A $25,000 Catch of Blackfish.

For the preparation of the finest oils, known as "Virgin oil," only the pulp of olives picked by hand is used. The pulp is packed in strong linen and the oil is expressed by twisting the linen together. The pulp sometimes contains as high as 70 per cent of oil.

Its last traces of adhering acid are removed by rigorous and repeated shaking with one hundredth part of their weight [Pg 15]of caustic soda lye. After the mixture has stood for several days a large quantity of water is added and the oil floating on the top is poured off.

Though the oil is now free from acid, it still contains coloring matter and other substances which would prove injurious. It is then mixed with very strong alcohol, ten parts of the former to two of the latter, and thoroughly mixed by shaking. The bottle containing the mixture is then placed in the sun and the mixture shaken several times a day. In the course of two or three weeks the oil will have become white as water, when it is withdrawn from the alcohol, on the surface of which it floats. The purified oil is placed in small bottles, tightly corked, and kept in a dark, cool place. (68.)

Fig. 3.—Relative Size of a Blackfish and Man.

Fig. 3.—Relative Size of a Blackfish and Man.

Fig. 4.—D. C. Stull's Watch Oil Factory, Provincetown,

Mass.

Fig. 4.—D. C. Stull's Watch Oil Factory, Provincetown,

Mass.

11. Mineral Oils have of late years taken immense strides in the popular and merited estimation of consumers, for general lubricating purposes. Their application in horology will be discussed in another part of this volume. They are obtained from the residuum of petroleum distillation, and vary so greatly in their properties that many of them are not applicable to delicate mechanism; but as the lighter varieties seem to fulfill all the necessary conditions, the writer will here consider their source and method of treatment.

12. Petroleums are obtained from many different localities, being fluid, bituminous oils, all having the same general characteristics and origin. They are all hydrocarbons, and contain little or no oxygen. As their origin is thoroughly discussed in many works on that subject, and as there is such a diversity of opinion regarding it, the reader is referred to such works.[3]

13. Paraffine, both liquid and solid, is obtained by the distillation of crude petroleum by means of superheated steam. When the heavier hydrocarbons begin to come over the receiver is changed and the butyraceous distillate is filtered through a long column of well dried animal charcoal. The first portion of the percolate is colorless or nearly so.

The distillate is made water white by some refiners by an acid treatment, followed by a water-and-alkali washing. On exposing this mass to a low temperature it becomes thick, somewhat like "cosmoline" but white. (59.) It is then shoveled into cotton bags of very strong material and subjected[Pg 18] to powerful pressure by means of a hydraulic press. This operation divides the paraffine into two parts: the solid paraffine wax from which candles, etc., are made remaining in the bags, while that which is expressed is paraffine oil. If the operation is carefully performed the oil will be free from crystaline paraffine at a very low temperature.

Fig. 5.—Extracting Oil from the Head of a Porpoise.

Fig. 5.—Extracting Oil from the Head of a Porpoise.

14. Neutral Oils[4] "are refined paraffine oils varying in specific gravity from 0.8641 to 0.8333. For the purpose [Pg 19]for which these oils are employed it is especially necessary that they be thoroughly deodorized. They are largely used for the purpose of mixing with animal and vegetable oils. It is said that a mixture of 95 per cent of a good neutral oil of the right gravity, and 5 per cent of sperm oil, has been sold for pure sperm. Ordinary inspection as to the odor and general appearance would fail to detect the adulteration. Having been subjected to the usual process for the extraction of crystaline paraffine, they will stand a very low cold test, and having been passed through bone black cylinders, they are free from odor and have but little color. They are usually exposed for a few days in open shallow tanks for the purpose of removing the flurescence of petroleum oils. Unmixed with heavier oils they are too light in body[Pg 20] (especially the lighter varieties) to be employed as spindle or machinery oils, but when mixed with such oils in the proper proportions they form admirable lubricating compounds for general lubricating purposes when very high speed is not required." (70-71.)

Fig. 6.—Rendering Room in D. C. Stull's Factory.

Fig. 6.—Rendering Room in D. C. Stull's Factory.

[1] Brannt. Animal and Vegetable Fats and Oils.

[2] Brannt. Animal and Vegetable Fats and Oils.

[3] Crew; Practical Treatise on Petroleum. Lesquereaux; Transactions American Philosophical Society. Winchell; Sketches of Creation. Henry; Early and Later History of Petroleum.

[4] Crew. Practical Treatise on Petroleum.

15. Most of those who may read this work, are no doubt familiar with the laws of elementary physics; but as all may not be, for a better understanding of that which follows, it may be well to treat briefly of some of the physical laws bearing on the subject.

16. The Molecule.[5] Every visible body of matter is composed of exceedingly small particles called molecules. This is the basis of the theory of the constitution of matter which physicists have usually adopted. It is estimated that if we should attempt to count the number of molecules in a pin's head, counting at the rate of 10,000,000 per second, we should require 250,000 years.

17. Porosity. The term pore in physics is restricted to the invisible space that separates molecules. All matter is porous; thus dense gold will absorb (24) liquid mercury, much as chalk will water; but the cavities to be seen in a sponge are not pores.

18. Gravitation. That attraction which is exerted on all matter, at all distances, is called gravitation. Gravitation is universal, that is, every molecule of matter attracts[Pg 22] every other molecule of matter in the universe. The whole force with which two bodies attract one another is the sum of the attraction of their molecules, and depends upon the number of molecules the two bodies collectively contain, and the mass of each molecule. Hence, all bodies attract, and are attracted by, all other bodies.

In a ball suspended from the ceiling by a thread an attraction exists between the ball and the ceiling, but on account of a greater attraction existing between the ball and the earth, if we cut the thread the ball will move toward the earth, or in the direction of the greater attraction.

19. The Effect of Distance. Gravitation varies inversely with the distance by which two bodies are separated.

As the sun is many times greater than the earth, the attraction between the ball (18) and the sun would cause the ball to leave the earth and move toward the sun were it not for the fact that the ball is so much nearer to the earth than to the sun.

20. Cohesion. The attraction which holds the molecules of the same substance together so as to form larger bodies is called cohesion.

It acts only at insensible distances and is strictly a molecular force. It is that force which prevents solid bodies from falling apart. Liquids like molasses and honey possess more cohesive force among the molecules of which they are composed than limpid liquids like water and alcohol. The former are said to be viscous, or to possess viscosity.

21. Adhesion. That force which causes unlike substances to cling together is called adhesion. It is that force[Pg 23] which keeps nails, driven into wood, in their places. You can climb a pole because of the adhesion between your hands and the pole. We could not pick anything up if it were not for adhesion. Glue, when dry, possesses both cohesion and adhesion to a great degree.

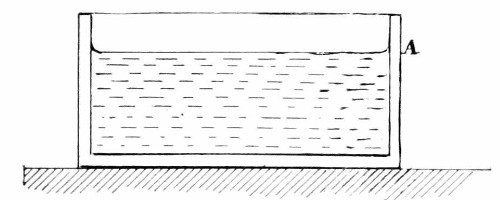

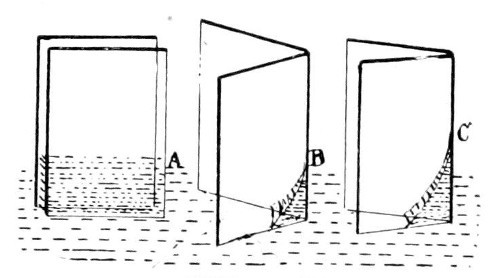

22. Capillarity. Examine the surface of water in a vessel. You find the surface level, except around the edge next the glass, as at A (Fig. 7.)

Fig. 7.

Fig. 7.

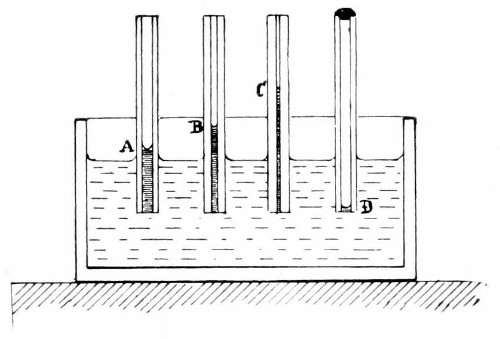

Fig. 8.

Fig. 8.

1. Thrust vertically into water three glass tubes, A, B and C (Fig. 8), open at both ends. You notice the water ascends in each to a different height, and that the ascension varies inversely as the diameter of the bore; i. e., the smaller the bore, the higher the water ascends.[Pg 24]

2. Seal one of the tubes at its upper end. The water enters but little, as shown at D (Fig. 8), on account of the resistance of the air pressure within the tube.

3. Thrust vertically two plates of glass into water, and gradually bring the surfaces near to each other. Soon the water rises between the plates, and rises higher as the plates are brought nearer. If their surfaces be mutually parallel and vertical, the water rises to the same height at all points between the plates, as shown at A (Fig. 9.)

Fig. 9.

Fig. 9.

4. If the plates be united by a hinge, and form an angle, the height to which the water ascends increases as the distance between the plates decreases up to their line of junction, where it attains a maximum, as shown at B (Fig. 9.)

5. Decrease the angle between the plates, and the water ascends higher, as shown at C (Fig. 9.) Thus it is seen that the ascension varies inversely with the angle between the plates; i. e., the smaller the angle, the higher the water ascends.

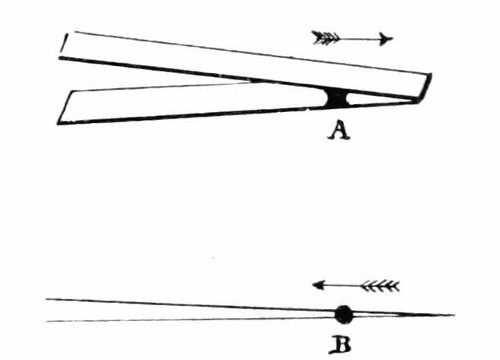

6. When a drop of oil is placed between two glass plates arranged as shown at A (Fig. 10), if the surfaces are not too far distant, and if the oil touches both surfaces, it will be seen to work its way to the junction of the plates; showing[Pg 25] that oil between surfaces has a tendency to flow towards the apex of the angle.

Fig. 10.

Fig. 10.

7. Place a drop of oil on a taper piece of metal, as shown at B (Fig. 10). The oil will gradually recede from the point to a place where there is more metal, showing that oil on surfaces has a tendency to flow towards the largest part.

Fig. 11.

Fig. 11.

8. When a drop of oil is placed between two watch glasses arranged with flat and convex sides adjacent, as at A (Fig. 11), or with convex sides adjacent, as at B (Fig. 11), if the glasses are rigidly fixed in their relative positions the drop of oil can be shaken from its location only with great difficulty; the oil at C holding its place with greater tenacity than the oil at D.[Pg 26]

The foregoing phenomena are called capillary action, or capillarity. Capillary action is due to the forces of cohesion (20), and to the forces of adhesion (21.)

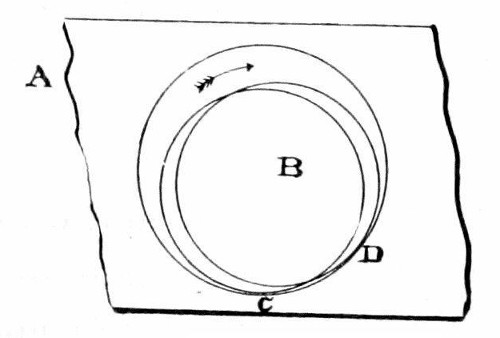

23. Centrifugal Force.—The tendency of a body rotating round a point to escape from that point is called centrifugal force.

Place a small quantity of oil on the arm of a balance, near the arbor. Rotate the wheel rapidly. The oil is seen to flow towards the rim of the wheel.

24. Absorption of Gases by Liquids depends on molecular attraction and motion. Water at a temperature of 0° cen. (32° f.), is capable of condensing in its pores (17) six hundred times its own bulk of ammonia gas. The absorption of oxygen from the air causes some oils to become more viscous, to eventually become solid, without losing in weight, in fact sometimes gaining. Other oils dry up, or evaporate, leaving little or no residue.

25. Force.—Force is that which can produce, change or destroy motion.

We see a body move; we know there must be a cause; that cause we call force. We see a body in motion come to rest; this effect must have had a cause; that cause we attribute to force. The forces acting in machines are distinguished into driving and resisting forces. That component of the force which does the work is called the "effort."

26. Friction is usually a resisting (29) force, tending to destroy motion; but it is sometimes the means of the transmission of motion.[Pg 27]

27. Work is the result of force acting through space. When force produces motion, the result is work. Work is measured by the product of the resistance into the space through which it is overcome.

28. Energy, which is defined[6] as the capacity for doing work, is either actual or potential. Actual or kinetic energy is the energy of an actually moving body, and is measured by the work which it is capable of performing while being brought to rest under the action of a retarding force.

Potential Energy is the capacity for doing work possessed by a body in virtue of its position, of its condition, or of its intrinsic properties. A bent bow or a coiled spring has potential energy, which becomes actual in the impulsion of the arrow or is expended in the work of the mechanism driven by the machine. A clock weight, condensed air and gunpowder are examples.

This form of energy appears in every moving part of every machine and its variations often seriously affect the working of machinery. (84.)

[5] This and some of the definitions that follow are adapted from "Elements of Physics" by A. P. Gage.

[6] Thurston. "Friction and Lost Work in Machinery," from which excellent work much of the next chapter is adapted.

29. Friction. The relative motion of one particle or body in forced contact with another is always retarded, or prevented, by a resisting force called friction.

Friction manifests itself in three ways: Between solids it is called sliding and rolling friction; between the particles of liquids, or of gasses, when they move in contact with each other, or with other bodies, it is called fluid friction. Quite different laws govern these three kinds of friction, as they are quite different in character.

Friction can never of itself produce or accelerate motion, being always a resisting force, acting at the surfaces of contact of the two particles, or masses, between which it occurs, and in the direction of their common tangent, resisting relative motion in whichever direction it may be attempted to produce it. The greatest loss of energy in a timepiece in which all the parts are rigid enough to prevent permanent distortion, is that occurring through friction. Another source of loss of energy is the reduction in elasticity of springs caused by a rise of temperature.

30. The Cause of Sliding Friction is the interlocking of the asperities of one surface with those of another; and only by the riding of one set over the other, or by a rubbing down or tearing off of projecting parts, can motion take place. It follows, then, that roughness is conducive to[Pg 30] friction; and that the smoother the surface the less the friction will be.

31. The Cause of Rolling Friction is the irregularity and lack of symmetry of the surfaces between which it occurs. It acts as a resisting, or retarding, force when a smoothly curved surface rolls upon another surface, plane or curved.

Motion is prevented, or retarded, by the irregular variation of the distance between the center of gravity and the line of motion in the common tangent of the two bodies at the point of contact, caused by the irregularity of form, or of surface, in the one or the other body. Rolling friction is small where hard, smooth, symmetrical surfaces are in contact, and increases as the surfaces are soft, rough or irregular.

In a knife edge support, seen in some forms of pendulums, is exhibited a form of rolling friction.

32. Solid Friction, either sliding or rolling, could be overcome if it were possible to produce absolutely smooth surfaces. It is evident, then, that the character of the material, as well as the form of their surfaces, determines the amount of friction.

In all time-keeping mechanism both sliding and rolling friction manifest themselves; the former principally between the surfaces of pivots and bearings and in the escapements, the latter mainly between the surfaces of the teeth of wheels, and to some extent in some of the pivots, and sometimes in parts of escapements. It is not the intention of the author to treat of the proper shape of the teeth of wheels,[Pg 31] leaves of pinions, or the proportions of the escapements, the nature and scope of this work not permitting of it; but he will confine his remarks principally to the parts that involve lubrication.

33. The Laws of Sliding Friction, as given by Thurston,[7] with solid, unlubricated surfaces, are, up to the point of abrasion, as follows:

1. The direction of frictional resisting forces is in the common tangent plane of the two surfaces, and directly opposed to their relative motion.

2. The point, or surface, of application of this resistance is the point, or the surface, on which contact occurs.

3. The greatest magnitude of this resisting force is dependent on the character of the surfaces, and is directly proportional to the force with which two surfaces are pressed together.

4. The maximum frictional resistance is independent of the area of contact, the velocity of rubbing, or any other conditions than intensity of pressure and condition of surfaces.

5. The friction of rest or quiescence, "statical friction," is greater than that of motion, or "kinetic friction."

He further states that these "laws" are not absolutely exact, as here stated, so far as they affect the magnitude of frictional resistance. It is found that some evidence exists indicating the continuous nature of the friction of rest and of motion.

When the pressure exceeds a certain amount, fixed for each pair of surfaces, abrasion of the softer surface or other[Pg 32] change of form takes place, the resistance becomes greater and is no longer wholly frictional.

When the pressure falls below a certain other and lower limit the resistance may be principally due to adhesion, an entirely different force, which may enter into the total resistance at all pressures, but which does not always appreciably modify the law at high pressures.

This limitation is seldom observable with solid, unlubricated surfaces, but may often be observed with lubricated surfaces, the friction of which, as will presently be seen (41), follows different laws. The upper limit should never be approached in machinery.

The coefficient of friction is that quantity which, being multiplied by the total pressure acting normally to the surfaces in contact, will give the measure of the maximum frictional resistance to motion.

34. Sliding Friction is Proportional to Pressure according to the third law quoted above. This is easily demonstrated by ascertaining what force is necessary to produce, or continue, motion in a body lying on a plane surface; double the weight of the body and the force required to produce, or continue, motion, will have to be doubled. The converse is also true (36).

35. Sliding Friction is Independent of the Area Of Contact, the pressure remaining the same (law 4, 33).

This is accounted for by the fact that if, for example, the area of contact be doubled, though twice the number of asperities will present themselves, each individual retarding[Pg 33] force is only half of what it was previously, and the general effect is the same (36).

36. The Intensity of Sliding Friction is Independent of Velocity. (Law 4, 33.) This is explained by the fact that the interlocking of the asperities on each surface has a shorter time to take place in increased speed, and consequently cannot be so effective as with slow speed. But with high speed more asperities are presented than in low speed, so the effect is the same in both cases.

The above (33-36) are not exact, being the statement of experimental laws, and admit of considerable modification when applied in horological science, as will be shown (41-42.)

Fig. 12.

Fig. 12.

37. The Effect of a Loose Bearing is an increase of friction, and consequently a loss of energy, resulting in the wear of one or both surfaces in contact, according to conditions. In Fig. 12, A is a loose bearing, B a journal at rest and C the point of contact. If the journal be now turned in the direction of the arrow by the motive force, it will have a tendency to roll over a short arc of the bearing to a new[Pg 34] point of contact, as at D, when it begins to slide; so long as the coefficient of friction is unchanged it retains this position; but approaches or retreats from the point C, as the coefficient of friction diminishes or increases, continually finding new conditions of equilibrium. The arc of contact is thus too small to withstand the pressure without abrasion of one or both surfaces.

It will thus be seen that the journal, or pivot, should fit its bearing closely; but it should be borne in mind that no tendency to "bind" should be produced, the fitting being such that the wheel will turn readily with a minimum pressure.

The film of oil which must be interposed between the bearing surfaces of the journal, or pivot, and its bearing, will also occupy some space; and this must be remembered, particularly in the case of pivots in the escapement.

38. The Laws of Rolling Friction are not as yet definitely established, because of the uncertainty of the results of experiments, as to the amount of friction due to (1) roughness of surface, (2) irregularity of form, (3) distortion under pressure.

The first and second of these quantities vary inversely as the radius; and the third depends upon the character of the material composing the two surfaces in contact.

It follows, then, that in such minute mechanical contrivances as are used in horology, as the motive force is in some cases very light, the horologist should endeavor to produce, where rolling friction takes place, the maximum—smoothness of surface—regularity of form—adaptation of surfaces (31.)[Pg 35]

There are many other points on which the writer would like to dwell, as engaging and disengaging friction, internal friction, etc., etc., but the scope of this paper will not permit.

39. The Friction Of Fluids in horology is of grave importance. It is subject to quite different laws from those met with in the motion of solids in contact. When a fluid moves in contact with a solid the resistance to motion experienced is due to relative motion of layers of fluid moving in contact with each other. At surfaces of contact with a solid the fluid lies against the solid without appreciable relative motion; as the distance from the surface is increased by layer upon layer of the fluid, the relative velocity of the solid and the fluid becomes greater. Fluid friction is, therefore, the friction of adjacent bodies of fluid in relative motion.

While fluid friction acts as a retarding force in mechanism it converts the mechanical energy required to produce it into its heat equivalent, thus raising the temperature of the mass in a greater or lesser degree.

The resisting property which thus effects this conversion, and which is the cause of fluid friction, is called viceosity.

It is thus apparent that a variation of the viceosity of the oil used on a watch would cause a variation of fluid friction and consequently a variation of the effort (11), and would seriously interfere with the rate of the watch. This will be discussed (84) more thoroughly in another paragraph.

40. The Laws of Fluid Friction are:

1. Fluid friction is independent of the pressure between the masses in contact.[Pg 36]

2. Fluid friction is directly proportional to the surfaces between which it occurs.

3. This resistance is proportional to the square of the relative velocity at moderate and high speeds, and to the velocity nearly at very low speeds.

4. It is independent of the nature of the surfaces of the solid against which the stream may flow, but it is dependent to some extent upon the degree of roughness of those surfaces.

5. It is proportional to the density of the fluid and is related in some way to its viscosity.

41. The Compound Friction of Lubricated Surfaces, as Thurston terms it, or friction due to the action of surfaces of solids partly separated by a fluid, is observed in all cases in which the rubbing surfaces are lubricated. The solids, in such instances, though partly supported by the layer of lubricant which is retained in place by adhesion (21) and cohesion (20), usually rub on each other more or less, as they are usually not completely separated by the liquid film interposed between them.

Wear is produced by the rubbing together of the two solids; and the rate at which the lubricant becomes discolored and charged with abraded metal indicates the amount of wear.

The journal and bearing are forced into close contact in the case of heavy pressures and slow speeds, as is shown by their worn condition; while the journal floats on the film of fluid which is continually interposed between it and the bearing, in the case of very light pressures, and high velocities; in the latter instance the friction occurs between two fluid layers, one moving with each surface.[Pg 37]

With heavy machinery, as the hardness and degree of polish of the surfaces cannot be increased in proportion to their weight, the solid friction is so great that while the interposition of a lubricant between the surfaces adds fluid friction, it also reduces the solid friction; and as the fluid friction is so insignificant as compared to the solid friction, the former is almost completely masked by the latter. In this case the laws of solid friction are more nearly applicable.

But in a delicate machine like a watch, especially in the escapement, where the power is so light, and where the rubbing surfaces are so hard, smooth and regular, the solid friction is so minute as compared to the fluid friction, that the former is relatively very slight, as compared with the latter. The laws of fluid friction are more nearly applicable in this instance.

There are thus, evidently, two limiting cases between which all examples of satisfactorily lubricated surfaces fall; the one limit is that of purely solid friction, which limit being passed, and sometimes before, abrasion ensues; the other limit is that at which the resistance is entirely due to the friction of the film of fluid which separates the surfaces of the solids completely.

42. The Laws of Friction of Lubricated Surfaces are evidently neither those of solid friction nor those of fluid friction, but will resemble more nearly the one or the other, as the limits described in the previous paragraph are approached. The value of the coefficient of friction varies with every change of velocity, of pressure, and of temperature, as well as with the change of character of the surfaces in contact.[Pg 38]

For perfectly lubricated surfaces, were such attainable, assuming it practicable with complete separation of the surfaces, the laws of friction, according to Thurston, would become:

1. The coefficient is inversely as the intensity of the pressure, and the resistance is independent of the pressure.

2. The friction coefficient varies as the square of the speed.

3. The friction varies directly as the area of the journal bearing.

4. The friction varies as the temperature rises, and as the viscosity of the lubricant is thus decreased (80).

43. The Methods of Reducing Waste of Energy Caused by Friction in time keeping mechanisms are based upon a few simple principles. It is evident that to make the work and power so lost a minimum, it is necessary to adopt the following precautions:

1. Proper choice of materials for rubbing surfaces (29-32).

2. Smooth finish and symmetrical shape of surfaces in contact (29-32 and 38).

3. The use of a lubricant the viscosity of which is adapted to the pressure between the bearing surfaces (80).

4. The best methods for retaining the lubricant at the places required, and for providing for a continual supply of the lubricant.

5. The bearing surfaces of such proportions that the lubricant will not be expelled at normal pressure.

6. The reducing of the diameters of all journals, shoulders and pivots, to the smallest size compatible with the foregoing[Pg 39] conditions, and with the stresses they are expected to sustain, thus reducing the space, through which the fluid friction acts, to a minimum (40); as well as reducing the distance from the axis of the arbor or pinion at which the friction, both solid and fluid, acts. The work done is independent of the length of the journal; except as it may modify pressure, and thus the coefficient of friction.

7. Proper fitting of bearing surfaces (37).

8. The reducing of the rubbing surfaces in escapements as much as the nature of the materials will allow without abrasion in the course of time (55).

44. Friction Between Surfaces Moving at Very Slow Speed, has been investigated by Fleming Jenkin and J. A. Ewing. A contrivance, which would be very excellent with some improvement, for the determination of the amount of friction under such conditions, is given in a paper[8] read before the Royal Society of London.

The arrangement employed by them was composed of a cast iron disk two feet in diameter and weighing 86 pounds. This disk, being turned true on its circumference, was supported by a spindle terminating in pivots 0.25 C. M. in diameter, the pivots resting in small rectangular bearings composed of the material the friction of which with steel is to be determined.

A tracing of ink was produced on a strip of paper which surrounded the disk, the ink being supplied by a pen actuated electrically by a pendulum, as in the syphon recorder.

As the traces thus left on the paper were produced without in any way interfering with the freedom of motion of[Pg 40] the disk, they afforded a means of determining the velocity of rotation.

The relative velocities of the pivot to the bearing surfaces varied from .006 C. M. to 0.3 C. M. per second, being the velocities met with in the various parts of time keeping devices.

Experiments were made with the bearing surfaces successively in three different conditions: viz. 1, dry; 2, wet with water; and 3, wet with oil; and gave the following results:

| SURFACES. | COEFFICIENT OF FRICTION. | |||

| JOURNAL. | BEARING. | DRY. | WATER. | OIL. |

| Steel | Steel | 0.351 | 0.208 | 0.118 |

| " | Brass | 0.195 | 0.105 | 0.146 |

| " | Polished Agate | 0.200 | 0.166 | 0.107 |

Several facts of great interest to the horologist are here shown. [9] Edward Rigg has this to say in regard to the apparatus of Jenkin and Ewing. "The friction, then, is true sliding friction without any rolling, and it will be evident that if the bearing were a circular hole just large enough to admit the pivot freely, the character of the friction would be in no way changed. In both a watch and clock the pivots are pressed against the sides of the pivot holes, either by the motive force or by gravity. There is no rolling round the pivot holes, so that the friction is all of the first kind. Jenkin's experiments[Pg 41] are, then, strictly applicable to the case of pivots,[10] and they constitute, so far as I am aware, the first scientific determination of the friction that occurs in time-keepers, and even in these experiments, the pressure, due to the weight of 86 pounds, is evidently too great, and thus too little regard is paid to the influence of adhesion."

E. Rigg further states that, reverting to the preceding table, we notice the following points of interest:—

1. "When the oil has dried up, the friction of a steel pivot in brass is actually less than in agate.

2. "A greater diminution of friction, by the application of oil, is effected when steel is used with steel, than where steel is used with brass or agate; although the fluid friction is probably equal in the three cases, when oil is used.

3. "With a perfect, non-drying, non-oxidizing lubricant, steel bearings for pivots would be preferable to brass bearings. Hence, with anything short of an approximately perfect oil, the brass is most serviceable.

4. "Brass pivot holes are much less affected by the drying of the oil than agate holes would be; and, in the absence of experiment, we must assume that this would be the case with ruby or other jewels.

5. "When the oil is perfectly fresh, agate and steel have a very low coefficient of friction."

How much these results would be altered by the use of a disk of such weight, and pivots of such proportionate size, as to meet the actual requirements in horology, remains to be ascertained.

Certainly the experiments of Jenkin, are not applicable to the pivots of a watch, as stated by E. Rigg; especially are[Pg 42] they not applicable to the friction of pivots in the escapement, where the laws of fluid friction are more nearly applicable; and when it is remembered that the weight of the disk was 86 pounds, and the pivots .25 c. m. in diameter, (or about the size of pivot of a large barrel arbor,) it is evident that the solid friction produced was much in excess of that produced in even the heavy part of the train of a watch.

Furthermore, even Jenkin and Ewing, in their paper, state "that, owing to the very great intensity of the pressure on the small bearing surfaces of the axle, the lubricants must have been to a great extent forced out." In a properly made watch, with a good lubricant, this does not occur.

But there can be no doubt that if the apparatus above described were so constructed as to meet the actual conditions in time recording instruments, very valuable data could be thereby secured. This could be done by reducing the weight of the disk, so as to make the weight bear the proper relation to the size of the pivots.

[7] Thurston. Friction and Lost Work in Machinery.

[8] Philosophical Transactions, 1877, Vol. CLXVII., p. 502.

[9] The Horological Journal, Apr., 1881. Vol. XXIII., page 98.

[10] The writer has italicised this phrase.

45. The scope of this work will not permit the discussion of the proper size, shape and construction of each and every part of all the various kinds of time-keeping mechanisms which have been produced. However a number of representative cases of friction and lubrication will be considered, and the laws applying to the same will be demonstrated. Practical methods of obtaining the best results will be shown and mistakes to be avoided will be pointed out.

The knowledge of what we ought not to do is sometimes of vastly greater importance than it is usually considered to be.

46. The Proportions of Pivots, Shoulders and Bearings, where the bearings are not capped jewels, should be such that the coefficient (33) of the combined solid and fluid friction will be a minimum, and such that the lubricant will not be expelled at normal pressure, while the "fit" (37) must be good.

1. The diameters of all pivots should be of the smallest size compatible (43,6) with the foregoing condition, and with the stresses which they are expected to sustain.[Pg 44]

2. The length of bearing surfaces is regulated by the pressures which may occur (43) between them, and by the nature of the materials of which they may be composed.

3. Given the diameter and the pressure, the length of the bearing surfaces can be so proportioned as to prevent abrasion and to present surfaces, between which the film of oil is interposed, of such magnitude that the lubricant will not be expelled at normal pressure.

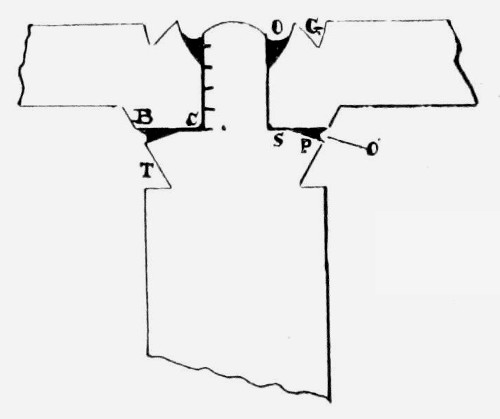

Fig. 13.

Fig. 13.

4. In Fig. 13 the length of bearing surface of the pivot is equal to its diameter, but the proportion must be varied according to conditions.

5. The barrel arbor pivots are sometimes necessarily of large diameter, and the bearing surfaces can be made shorter in proportion, as the surfaces will then be great enough to give good results as well as to retain (48) the oil.

6. In the center pinion (49) where the diameter of the the pivots is made small for reasons explained (43, 6), the length of the bearing surfaces must be such that abrasion will not occur, and that the oil will not be expelled.[Pg 45]

7. The rest of the train is subject to the same laws. The length of the bearing surfaces of the pivots remote from the motive force can be made shorter in proportion.

8. The diameter of the shoulder S, Fig. 13, is reduced to as small a size as will properly sustain the "end thrust," thus reducing the friction, both solid and fluid, to a minimum, at the same time reducing the distance from the center of the arbor (43, 6) at which the friction acts.

9. The above proportions vary with the nature of the material; where jewels are employed a shorter bearing surface may be used, if it be desired to reduce friction, but the pressure on the oil is the same with jewel as with brass bearings, so that it must not be made so short that the oil will be expelled.

47. The Shape of Pivots, Shoulders and Bearings, where the bearings are not capped jewels, should be such as to produce as little friction as possible. They should be hard, symmetrical, and smooth (30).

The construction should be such that a considerable amount of oil may be applied without having a tendency to spread.

The advantages of the construction shown at Fig. 13 are:

1. The oil sink O is deep and narrow, rather than wide and flat—thus causing the oil to be drawn towards the apex of the angle, i. e. towards the pivot, with greater force (22, 5) than if the oil sink were wide and shallow, in which case the oil would have a tendency to spread, as too often occurs.

2. The total length of the pivot is to the length of its bearing surface as 5 is to 3, thus further reducing the angle, which produces a greater tendency (22, 5) in the oil to stay in the oil-sink.[Pg 46]

3. A circular groove G is cut around the oil sink, which produces a still greater tendency on the part of the oil to stay in the sink, by removing metal which would otherwise exert an attraction (19) on the oil.

4. The beveled portion P is comparatively large—while the shoulder S is relatively small—thus forming the angle O´ of about 20° with the flat surface of the bearing. This will cause the oil to have a tendency to flow towards the pivot, for the reason given in considering the oil-sink.

5. The boss B is made to diminish the liability of the oil to spread, by a reduction (18-19) of the amount of metal which would otherwise cause it.

6. The back taper T is made for the same reason. Some watchmakers (?) seem to think this is added only for ornament, but it is a very important factor in producing longevity of the oil.

7. The slight chamfer C, in the bearing, serves two purposes; it becomes a reservoir for oil and removes any burr that might otherwise exist in a metal bearing, without in any way altering its effectiveness.

8. It will thus be seen that the oil reservoirs O, O´ and C are made to contain, and retain, the maximum amount of oil, and the supply of the lubricant is thus increased to a maximum length of time.

The application of these principles to each part to which they relate will be considered.

48. The Barrel Arbor, with its bearing, should be so constructed that the oil will not spread to the contiguous parts. The oil sink, with circular groove cut around the[Pg 47] outside (46-47), both in the barrel and its cover, should not be neglected.

It is well to apply oil to the bottom and on the cover of the barrel, as well as on the coils of the spring; and before putting on the cover, a small amount applied on the arbor nut at the shoulders will assist greatly in causing the oil to be at once drawn to its proper place.

Care must be exercised while and after cleaning the mainspring, in order that it may come in contact with the fingers as little as possible, as the acids contained in perspiration are liable to be transferred to the spring and so work serious injury by contaminating the oil.

A part frequently neglected is the point of contact of the click spring with the click. If this part be not oiled rust is likely to form, and many instances have occurred where rust has found its way all through the movement from this cause. In fact, this may be said of the point of contact of all springs, with few exceptions, both in plain and complicated work.

If the watch has a chain and fusee, these both should be looked after; the former can be well oiled, and the surplus wiped off so as to leave a minute quantity in the interstices of the links; while the latter should have oil on its clicks, as well as on the arbor where it passes through the wheel. If the ratchet of the maintaining power be of brass it should not be oiled; while if it is of steel oil should be applied. Its click should have the pivots of its arbor oiled, while what was said of clicks in general will apply here.

49. The Center Pinion Pivots, with their bearings, should be very carefully constructed, as this is the vulnerable[Pg 48] point of most watches. With proper precautions (46-47) these parts can be made so as to wear as long as the rest of the watch.

In a high-priced watch the bearings should be jewels; but in a cheap watch, where the price will not warrant correct work and careful fitting, the bearings are preferably of brass or some other metal.

Where the bearings of the center pinions are of brass or nickel, there is little difficulty experienced in making them perfectly "upright"—a condition necessary to produce a minimum amount of friction—while, if the bearings are jewels which are not upright, the friction, and consequent wear, will be increased. Properly jeweled bearings produce a maximum durability, as they cause the least friction; while the coefficient of friction is subject to much less fluctuation on account of the harder, smoother surface of the jewel, (43, 46, 47 and 61).

Where there is a brass bearing for the lower pivot, in watches having a solid center arbor on which the cannon pinion revolves in setting, the length of the bearing may be profitably increased by making a boss on the outer side of the lower plate, provision for which is then made in the cannon pinion by a suitable recess. In either case the laws previously given should be complied with.

A source of mischief in many watches is the manner in which the minute wheel is made; the construction being such that its teeth touch the plate so near the bearing of the center arbor that capillary attraction (19, 22) is produced, which causes all the oil to leave the lower bearing of the center arbor. This can be avoided by cutting off the lower parts of the teeth of the minute wheel; or, by turning a[Pg 49] groove in the plate which will be concentric with the minute wheel post, and which will pass under the teeth of the wheel, but not near enough to the bearing of the center arbor to injure the latter.

The oil from the stem wind mechanism, also, sometimes flows under the minute wheel, and from there into the center arbor bearing; and, when the oil is used up in the former place, it is drawn up again out of the latter place leaving it dry. A means of preventing this will be discussed (59) later.

Another and very frequent cause of the lower center pivot cutting, particularly in new watches, is the neglect to remove the polishing material from the cannon pinion where the center arbor is solid.

A small portion of oil should be applied to the bearings of the minute wheel, (where its pinion, or the pivot on which it revolves, is steel), hour wheel, and cannon pinion where the center arbor is solid, and to the set hands arbor where the center arbor is hollow. The safety pinion should always be oiled, as it may not otherwise be of much service.

50. The Third Pinion Pivots are sometimes the source of mischief. When the center wheel is placed above or below the barrel, the upper or lower pivot of the third pinion receives such great stress that the oil is forced out in many cases. By increasing the length of the pivot this could be obviated. The minute wheel is sometimes so close to the lower bearing of this pinion as to absorb the oil. This can be remedied by cutting a recess in the lower side of the minute wheel. Where it is possible to do so the wheels should be so placed on their pinions and arbors, and at such a distance from the bearing surfaces of the latter, that the[Pg 50] stress on each pivot—the combined result of the weight of the wheel and the forces acting on it—will be equal.

51. The Fourth Pinion Pivots should follow the same general laws as that given for the rest of the train; but it should be borne in mind that fluid friction acts as a retarding force much more perceptibly in the lighter parts of the train; consequently if no second-hand is to be carried, very small bearing surfaces should be the rule in this case.

52. The 'Scape Pinion Pivots as well as the shoulders should not be too large, while there should be sufficient back taper to insure the oil remaining at the pivots. A very small quantity of oil should be applied, as, when too much is used, it is liable to work up into the pinion where the latter is short, as in very thin watches, thus producing, when very fine dust is added, a mixture that acts much like oil stone power and oil, which cuts away the leaves of the pinion.

53. The Lever Arbor Pivots should also be small, with small shoulders so as to reduce fluid friction to a minimum.

It may be well to add that in all uncapped bearings of pivots in the train, whether they be of jewels or of brass, a slight convex shape can profitably be given to the surface where the shoulder of the arbor, or pinion, touches the bearing, thereby reducing not only the surface of contact at the shoulder, and consequently diminishing the cause of friction (41), but by reducing the distance from the center, at which the friction acts, the retarding effect of the friction is much less (46), thus obtaining a greater effort (25).[Pg 51]

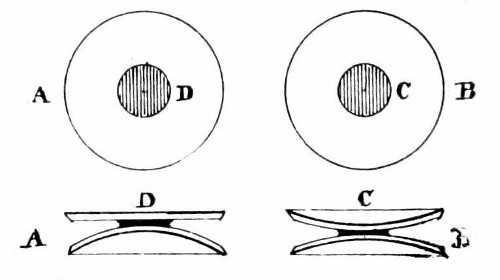

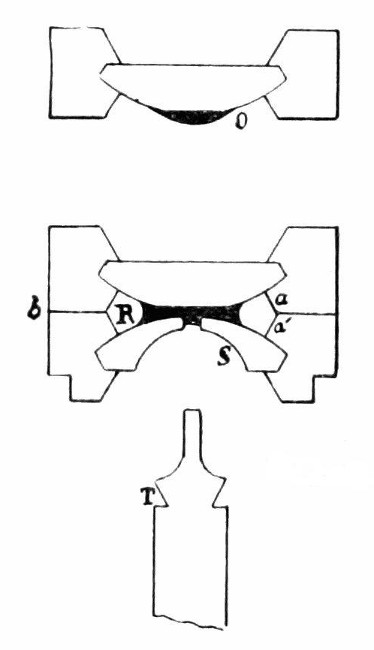

54. The Balance Arbor Pivots and Bearings, as well as those of the lever and scape wheel where their pivots run in capped jewels, deserve particular attention. Fig. 14 shows hole and cap jewels in settings, but what applies to them is equally applicable to all capped jewels, with few exceptions.

Fig. 14.

Fig. 14.

In Fig. 14 all the laws of capillary action are applied. It has been shown (22,8) that, when two watch glasses are fixed rigidly relatively with their convex sides adjacent, if a drop of oil be placed near their centers it can be shaken from its position only with great difficulty.

The jewels, in this instance, present much the same form, though only a minute quantity of oil, instead of a drop, is involved; but the same influences are at work in both cases.

This reservoir, if properly made, will contain enough oil to last a long time; as, when the oil in the center is used up,[Pg 52] that which is nearer the settings will be drawn to the pivot. The writer has said "nearer" the settings; but it is very important that the oil should never touch the setting (58).

Both settings are cut away at aa´, in order that as little attractive influence (22) as possible may be exerted on the oil by the metal in the settings.

Where the adjacent surfaces of the hole and cap jewel are flat and parallel the oil will usually have a tendency to be drawn to the setting—the evil effect of which will be shown (58) later—especially if the hole and cap jewel are at any appreciable distance from each other; while if they are too close together, the reservoir will not be sufficiently large.

The conical pivot shown is the usual form in the finer grades of American watches; and as this form of pivot combines strength with a minimum tendency to attract the oil from the jewel hole, it is to be highly recommended. The back-taper T should never be neglected for reasons previously (47, 6) given. The proportions that should exist between the diameter of the pivot and the length of its bearing surface, as well as the shape of the end of the pivot, cannot be discussed here, as the scope of this work will not permit; but it should be borne in mind that the smaller the pivots, consistent with strength, the less the fluid friction will be. The sides of the pivots should be straight and parallel for a minute distance from their bearing surfaces; while the form of the rest of the pivot should be a gradually increasing curve, terminating at the point where the back-taper begins.

The proper proportion of the diameter of the pivot to the diameter of the jewel hole varies according to conditions; but[Pg 53] it has been previously (37) shown in a general way what this should be.

55. The Escapements should be constructed in such a way that a maximum durability of oil may be secured. The acting surfaces of the teeth of the scape wheels should be made as small as possible consistent with durability (43, 8); while enough metal should be left near the acting surfaces to be sufficient to retain the oil and prevent its attraction to the web of the wheel. The teeth of chronometer scape wheels should not be oiled, as it is liable to seriously alter the rate. When the oil becomes viscous by oxidation or by cold it would produce too much variation of fluid friction and so diminish the effort (25) of the mechanism. Some watchmakers oil the fork of the lever in anchor escapements very slightly, by applying oil and then using pith to remove any surplus, while others never oil the fork. The writer has frequently observed ferric oxide or "rust" on the roller, fork, and on the plate or potance; but whether this was the result of not oiling or of oil having been applied which afterward become gummed, or evaporated, it would be interesting to know.

56. The Curb Pins sometimes produce the ferric oxide mentioned by their action on the hairspring. This has been remedied by the same method as used in the fork just referred to, and if a very minute quantity of oil can be applied—such a minute quantity that if the whole spring were equally covered by a coating of oil equally thin, such film being so thin that it would have no tendency to cause the coils to adhere, or to cause small particles of matter to adhere—then it may be that this method deserves notice.[Pg 54]

By making a solution of benzine and oil (100 drops of the former with 1 to 10 drops of the latter) and by immersing the hairspring in this solution and on withdrawing it dry it quickly between soft, fine linen, it will be found that the coils of the hairspring do not adhere to each other. The effect that this would produce on the whole spring by way of preventing rust in damp, warm climates, will be stated (78) later.

57. The Application Of Oil must be attended with great care. The shoulders of the barrel and center arbors may be profitably oiled before putting them in their places, applying an additional small amount afterward. The rest of the pivots should be oiled after the movement is set up—except in the case of capped jewels—as if oil is applied to each pivot as the wheel is put in position it would be difficult to keep the oil in good condition and at its proper place if it should be necessary to take the movement apart again for any purpose.

The oil is more evenly distributed on the teeth of scape wheels, where such require lubrication, if a small quantity of oil be applied to each tooth, or every second or third tooth. A small amount added to the surfaces on which the teeth act will in most cases be beneficial. If it be necessary to take the movement partially apart for any purpose, after it has been oiled, care should be taken not to give the train a too rapid motion, as the centrifugal force (23) resulting from the rapid circular motion of the wheels will be liable to cause the oil to leave the jewel holes and spread upon the surfaces of the jewels, and also cause the oil to fly off the teeth of[Pg 55] the scape wheel to its determent and that of other parts which are better without oil.

58. The Method of Oiling Capped Jewels has been given by Saunier, as follows:[11] "When a drop of oil is introduced into the oil cup of the balance pivot-hole, insert a very fine pegwood point, so as to cause the descent of the oil. When this precaution is not taken, it frequently happens that in inserting the balance pivot its conical shoulder draws away some of the oil, and there is a deficiency both in the hole and on the endstone." In both the English and American editions, this erroneous method is repeated.

By this means, only an insufficient quantity of oil can be caused to flow into the reservoir, as the pressure of the air inside will prevent the oil flowing in; as, in the case of a glass tube with the upper end sealed up, it has been shown (22, 2) that the water refused to be drawn up the tube, even with the added pressure caused by the lower end of the tube being below the water line. Again, the point of pegwood is liable to have minute fibres of wood adhering to it, which will be incorporated with the oil; and its liability to break off, and remain in the jewel hole, is another reason why pegwood should never be used. The author advances a method, which is not open to these objections, as follows: When about to place the cap jewel in position—after the hole jewel is in place if it be in a setting—a small quantity of oil is placed ON THE CAP JEWEL, as shown at O, Fig. 14, being very careful to allow no oil to spread upon the cap jewel setting. This setting is then carefully placed in position; when the oil, if the operation has been skillfully[Pg 56] performed, is seen to be collected in the reservoir R and in the jewel hole. The appearance which it will assume is shown in Fig. 14. The advantages which this method possesses are: the reservoir can by this means be made to contain the maximum quantity of oil; and the oil cup or sink S is left with its surface dry, thereby exposing less oil to the influences of the air; and, at the same time the tendency of the oil to flow towards the shoulder of the pivot is decreased.

Skill is necessary in order to judge of and place the requisite amount of oil on the cap jewel before putting it in position; as, if too much is used it is worse than if too little is employed, because the oil would then flow on to the setting, and from there between the settings at b, when it will rapidly be all drawn from the bearing, leaving it dry, while the settings are copiously supplied. The approximate relative position which the oil should occupy is shown at d, Fig. 14, in section; and this can be seen by looking through the jewels with a double eye-glass, when a true circle, concentric with the jewel hole, will be seen to have formed. This circle represents the limit of the distance which the oil has flowed from the jewel hole. When too much oil has been applied, this limit is not a circle, but represents a U.

In the example given, the upper surface of the cap jewel is made flat, while the lower surface is made convex with a flat space in the center; as a better view of the end of the pivot and the condition of the oil can be thereby obtained.

In no case should the contiguous surfaces of the hole and cap jewel be both made flat; as, when their planes are vertical, the oil will be drawn downwards by gravitation (18), there being no counteracting force (22) to keep the oil in[Pg 57] place. The author has remedied this defect, in many instances, by cutting a groove around the jewel, leaving only enough metal near the jewel to hold it, and enough near the edge of the setting to rest solidly against the other setting.

In some watches, particularly those of Swiss make, the jewel bezels—both cap and hole—are brought well up around the jewel, while a groove is cut around the jewel bezel. In this instance the oil may be made to cover the whole inside surface of both jewels, as the groove will prevent the oil from flowing away to parts where it is not required.

The reprehensible practice of replacing a broken cap jewel by cutting away the bezel and placing the new jewel in loosely, cannot be too severely condemned. The new cheap foreign-made watches contain this objectionable feature in many instances.

Where the jewels are in settings, sharp instruments, as tweezers, etc., should never be used to push the settings in place; as the projections produced in this manner would not only injure the appearance of the settings, but would prevent their close contact. Thoroughly clean, well-finished jewel pushers are indispensable; as even pegwood is liable to leave fibres at least.

The shape of the oiler is a matter of some importance; as with a poorly-made oiler it is next to impossible to do work satisfactorily. The tip is preferably of gold, tapering towards the end to about the size of a second's hand pivot of an eighteen size American movement; but at the end it should be about three times as wide and flat. A nickel fastened to the end of a lead-pencil will give the idea approximately. This large end will cause the oil to remain where it may be[Pg 58] readily applied to the bearing surface, instead of flowing back on the oiler towards the handle, as it would (22, 7) if the point were tapering.

59. The Stem Winding Mechanism should be thoroughly well made, always keeping in view that the laws of capillary attraction must be complied with.

Wherever an angle can be formed, with its apex pointing towards the place where the oil is required to remain, it should be done.

A very good lubricant for stem wind parts is found in stearine, from which the animal oils are expressed at cold temperatures, as it is very thickly fluid at ordinary temperatures; while an excellent lubricant for this purpose is paraffine—not the wax nor the oil, but that white, soft substance from which both are obtained (13 & 73). Stearine and paraffine both possess great viscosity; and, though the fluid friction is increased by their use, the solid friction is diminished. Then, too, the tendency to spread is very much less.

60. The Pendant is frequently a cause of trouble to the watchmaker. It is very important that the winding stem be lubricated with a substance that will not spread at ordinary temperatures. The lubricant should be applied at all places where steel rubs on steel or other metal. The winding stem and case spring, and the sleeve if present should have as much as can be safely applied; as they are so much exposed that rust often forms, which finds its way down through the movement, frequently resulting in serious damage to the delicate parts. The bearings of collet on stem and the pendant screw should also be lubricated.[Pg 59]

Attention to these details will also prevent "that squeaking sound" which, sometimes occurring shortly after a watch has been repaired, causes the owner to believe that the work was not done properly.

The lubricants just mentioned (59) serve admirably for this purpose.

61. The Cause of the Cutting of Pivots, in addition to the effect of friction (32, 1) and other causes which have been mentioned (49), may be that minute currents of static electricity are induced between the surfaces of the pivot and bearing, the oil acting as the electrolyte.

If this be the case, the cause of pivots turning black would appear to be explained—the molecules of iron becoming electrically disassociated from the molecules of carbon, the latter being by their nature black, and being now on the surface in sufficient quantities to make themselves evident, give the surface the black color. Such is the first stage of "cutting."

The molecules of iron, becoming incorporated in the now thick and viscous oil or imbedding themselves in the bearing, act as an abrasive; the black surface is removed, making the pivot again bright, but "ringed." The molecules of iron, uniting with the molecules of oxygen which exist in the oil in its oxidized state, forms ferric oxide.

Ferric oxide is known as colcothar, English-Roth, rouge, crocus, etc.

The above theory is advanced by the author for what it may be worth, as it seems to explain this curious phenomenon.

[11] Saunier. Watchmakers' Handbook.

62. Lubrication has for its objects, both the reduction of friction and the prevention of excessive injury from wear; and the mechanician resorts to the expedient of interposing between the rubbing surfaces a substance having the lowest possible coefficient of friction with the greatest possible capacity for preventing wear.

The valuable qualities of lubricants are determined by their power of reducing friction, and by their endurance as well as that of the surfaces on which they are used. The amount of frictional resistance to the motion of machinery is obviously determined by the character of the lubricating material.[12]

63. The Animal Oils have had a wide and varied application in general machinery, and much testimony might be produced to show the superiority of any one kind over all the other kinds. Each variety has some particular property which some of the others may not have to such a degree.

64. Porpoise Jaw Oil[13] and Blackfish Melon Oil have certain good qualities which have made them very[Pg 62] popular, particularly on this side of the Atlantic. When properly refined (4-6) they are no doubt very suitable for the work of reducing friction in small and delicate mechanism.

65. Sperm Oil (7) had been used to some extent as a lubricant for time-keeping contrivances; in fact, many tower clock experts still employ it on the heavier bearings. A. Long, writing to the British Horological Journal, describes a trip to the Arctic regions in 1814 and 1815, in which he states that a certain portion of the sperm oil they obtained never congealed, which they preserved and applied to their chronometers, and thus kept them going through the winter.

Others have experimented with it, and it was at one time largely used; while some tower clock makers claim that they find it satisfactory. It is, however, open to the objection that it would produce serious variation when used in time-keeping mechanisms, as its viscosity varies greatly with varying temperatures caused by the alteration of the spermaceti it contains, thus causing sudden fluctuations of its coefficient of friction (81). It also absorbs oxygen rapidly when it is exposed to the air and loses quality seriously, gradually becoming "gummed" or resinous. A gain of two to three per cent in weight in twelve hours when exposed to the air at 140° F. (60 C), is caused by this absorption of oxygen (10).

66. Bone Oil (8) has been widely used both in this country and in Europe, and possesses some good qualities, not the least of which is the property of resisting evaporation and oxidation.[Pg 63]

67. Neatsfoot Oil (9) has been largely used, especially in Europe. The writer regrets that he has not procured samples in order to ascertain its relative value.

68. Olive Oil (10) has at least one good quality. It is one of the most perfectly non-drying of all the oils, resisting both oxidation and evaporation (24). But it is next to impossible to entirely remove its acid qualities, small traces of which remain after the most thorough treatment. It is also liable to decomposition, generating acids even after refinement.

69. Mineral Oil (11) has been used as a lubricant for time keeping mechanism; but as there are so many varieties on the market, each differing from the others and possessing properties peculiar to itself, and as many have made experiments which have not demonstrated that such oils possess all the essential qualities of a perfect lubricant in horology, the author believes that the abundance of kinds and qualities of mineral oils has in the past been more or less confusing to the majority of those who have experimented; and believes further, that if the proper kind and quality of such oils had been used, all that could be desired in a lubricant would have been shown to have been contained therein.

Past experience has shown that many lubricants remained for years unused for special purposes to which, when tried, they were found specially adapted.

Though E. Rigg was probably in error in the matter previously discussed (44) his otherwise excellent lecture contains the following:—[14]

"But there is another subject that has a still closer bearing on friction as met with in time keeping instruments, and I cannot bring my lecture to a close without reference to that most fruitful source of trouble to the watchmaker—oil. Breguet, a very famous horologist, and D'Arcet, an equally celebrated chemist, worked together at this problem and what was the result? They produced an oil that was, according to their theory, perfect; but when applied to watches it proved to be worse than the ordinary oils of commerce. Since their day the chemistry of oil has not made much progress, and the methods recommended for testing oil are still very ineffectual. The only test of any use is actual trial for a long period, and under varying conditions as to temperature, nature of atmosphere, etc.; and there are several oils on the market more or less satisfying the required conditions. So far as my knowledge goes, however, all are liable to dry; and this prompts me to draw your attention to a lubricator that has come into use for heavy machinery in recent years, in the hope that it may afford a suggestion for the improvement of watch oils. I allude to the mixture of certain kinds of mineral oil with an oil that has a tendency to dry. Even a small percentage is asserted to entirely check this tendency and the resulting mixture is said to have the property of not in any way acting on or damaging the metal to which it is applied. The thickness, or 'body,' is made to vary according to the pressure to which the oil is subjected. * * * * Would it be oversanguine to hope that some such mixture, prepared from perfectly pure materials, might help even the chronometer maker to secure more uniform rates? Absolute freedom from acidity means[Pg 65] a reduction of such electrical action as may occur at the pivots, and, therefore, a greater permanency of the oil from this point of view."

70. Neutral Oil (14) seems to be especially adapted for use in horology. Used in a pure state, or mixed in variable quantities with a good animal oil, it can readily be made to fulfill the various conditions required in all parts of watches, chronometers, mantel and tower clocks.

It is usually sold as such, but sometimes under the names "liquid paraffine," "glycoline," "albolene," etc., while "solid paraffine," "white cosmoline," "solid alboline," are the names given to the thick butyraceous mass from which neutral oils are made. Sometimes this substance, as well as the liquid paraffine, is medicated or perfumed; but it is hardly necessary to state that when thus treated it is unfit for use in horology.

71. The Properties of Neutral Oil are stated to be:[15]

"It is a clear oily liquid, having a specific gravity of not less than 0.840 and boiling not below 360° C. (680° F.). It should be free from colored, fluorescing, and odorous compounds.

"When heated for a day by means of a water bath, the paraffine should not become dark colored, and the sulphuric acid should become only slightly brownish. Metallic sodium treated in a similar manner should retain its metallic lustre. Alcohol boiled with paraffine should not have an acid reaction."

72. The Properties of Solid Paraffine (13) are given as follows:[16]

"The melting point of commercial paraffine varies much. Obtained from the residuum of petroleum distillation it is usually 43° C. (109.4 F.), or somewhat higher."

The acid and metallic sodium tests given for liquid paraffine will apply to the solid paraffine.

73. The Value of a Lubricant as a lubricant is independent of the market price; and it is at a maximum, according to Thurston, when it possesses the following characteristics:

1. Enough "body," or combined capillarity and viscosity (82), to keep the surfaces between which it is interposed from coming in contact at maximum pressures.

2. The greatest fluidity consistent with the preceding requirements, i. e., the least fluid friction allowable.

3. The lowest possible coefficient of friction under the conditions in actual use, i. e., the sum of the two components, solid and fluid friction, should be a minimum.

4. A maximum capacity for receiving, transmitting, storing and carrying away heat.

5. Freedom from tendency to decompose or to change in composition by gumming or otherwise, on exposure to the air (79) while in use.