Title: Engineers and their triumphs

Author: F. M. Holmes

Release date: October 2, 2022 [eBook #69084]

Language: English

Original publication: United States: Fleming H. Revell Company

Credits: Fiona Holmes and the Online Distributed Proofreading Team at http://www.pgdp.net (This file was produced from images generously made available by The Internet Archive/American Libraries.)

Hyphenation has been standardised.

The Transcriber has constructed a ‘List of Illustrations’, as none was supplied.

Page 132—changed possibilites to possibilities

THE STORY OF THE LOCOMOTIVE—THE STEAMSHIP—BRIDGE BUILDING—TUNNEL MAKING.

BY

F. M. HOLMES,

AUTHOR OF “FOUR HEROES OF INDIA,” ETC.

FLEMING H. REVELL COMPANY

NEW YORK CHICAGO TORONTO

Publishers of Evangelical Literature.

PREFACE.

Without attempting to be exhaustive, this little book aims at describing in a purely popular and non-technical manner some of the great achievements of engineers, more particularly during the nineteenth century.

The four departments chosen have been selected not in pursuance of any comprehensive plan, but because they present some of the more striking features of constructional effort. The term Engineering, however, includes the design and supervision of numerous works, such as roads and canals, docks and break-waters, machinery and mining, as well as steam-engines and steamships, bridges and tunnels.

Information, in certain cases, has been gained at first-hand, and I have to acknowledge the courtesy of the managers of the Cunard and White Star Steamship Companies, Messrs. Maudslay, Sons & Field, and others, in supplying various particulars.

The narrative concerning Henry Bell and the steamship Comet, and of his connection with Fulton, is chiefly [vi] based on a letter from Bell himself in the Caledonian Mercury in 1816.

The statement that Mr. Macgregor Laird was so largely instrumental in founding the British and American Steam Navigation Company is made on the authority of his daughter, Miss Eleanor Bristow Laird. An article on “The Genesis of the Steamship,” which I wrote in the Gentleman’s Magazine, brought a letter from that lady in which she declares that her father was the prime mover in founding the Company. He had had experience, in the Niger Expedition of 1832-33, of the behaviour of steamships both at sea and in the river, and from the date of his return to England she asserts he advocated the establishment of steam communication between England and America, against the active opposition of Dr. Lardner and others. “Macgregor Laird’s claim to the foremost place amongst all those (not excepting Brunel) who worked for the same object,” writes Miss Laird, “was clearly shown in a letter from the late Mr. Archibald Hamilton of 17 St. Helen’s Place, E.C., to the editor of the Shipping and Mercantile Gazette, in which paper it was published on 15th May, 1873.”

It is not a little curious to note how, in many of these great undertakings, several minds seem to have been working to the same end at about the same time. It was so with George Stephenson and others with regard to the locomotive, with Miller and Symington, Bell and Fulton, with regard to the steamship, with Laird and Brunel as regards transatlantic steam navigation, with Robert Stephenson and William Fairbairn as regards the tubular bridge.

This volume does not seek to be the special advocate of any, or to enter into any minute details, but simply endeavours to gather up the more salient features and weave them into a connected and popular narrative.

F. M. HOLMES.

| THE STORY OF THE LOCOMOTIVE. | ||

| CHAPTER | PAGE | |

|---|---|---|

| I. | FIRST STEPS, | 9 |

| II. | GLANCING BACKWARDS AND STRUGGLING FORWARDS, | 19 |

| III. | FIFTEEN MILES AN HOUR, | 28 |

| IV. | A MARVEL OF MECHANISM, | 36 |

| V. | A MILE A MINUTE, | 46 |

| THE STORY OF THE STEAMSHIP. | ||

| I. | THE “COMET” APPEARS, | 53 |

| II. | TO THE NARROW SEAS, | 60 |

| III. | ON THE OPEN OCEAN, | 68 |

| IV. | THE OCEAN RACE, | 74 |

| V. | BEFORE THE FURNACE, | 85 |

| FAMOUS BRIDGES AND THEIR BUILDERS. | ||

| I. | “THE BRIDGE BY THE EARTHEN HOUSE,” | 101 |

| II. | A NEW IDEA—THE BRITANNIA TUBULAR, | 108[viii] |

| III. | LATTICE AND SUSPENSION BRIDGES, | 119 |

| IV. | THE GREATEST BRIDGE IN THE WORLD, | 125 |

| V. | THE TOWER BRIDGE, | 133 |

| REMARKABLE TUNNELS AND THEIR CONSTRUCTION. |

||

| I. | HOW BRUNEL MADE A BORING-SHIELD, | 137 |

| II. | UNDER THE RIVER, | 141 |

| III. | THROUGH THE ALPS, | 147 |

| IV. | UNDER WATER AGAIN, | 153 |

| The Tower Bridge, London, showing the bascules raised. | iii |

| George Stephenson. | 11 |

| “Puffing Billy,” the oldest locomotive engine in existence. | 13 |

| James Watt. | 21 |

| Edward Pease. | 27 |

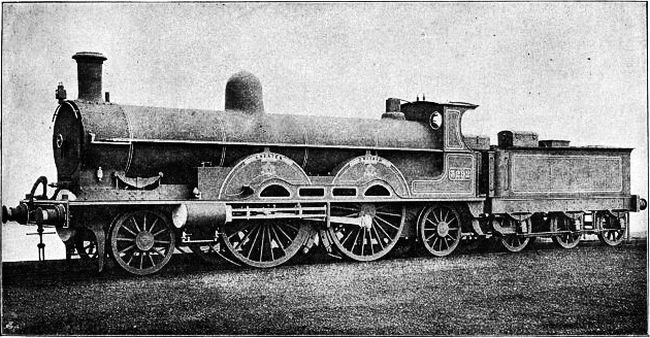

| The compound locomotive “Greater Britain.” | 41 |

| Back and front view of the locomotive “Greater Britain.” | 44 |

| The “Flying Dutchman.” | 50 |

| Bell’s “Comet.” | 55 |

| Robert Fulton. | 59 |

| The ice-bound “Britannia” at Boston. | 77 |

| Isambard Kingdom Brunel. | 80 |

| The “Great Eastern.” | 83 |

| High and low pressure cylinders of the “Campania’s” engines. | 87 |

| The “Campania.” | 89 |

| Stoke Hole. | 93 |

| Promenade deck of the “Paris.” | 99 |

| Pontypridd Bridge. | 102 |

| The Post Bridge, Dartmoor. | 105 |

| Robert Stephenson. | 111 |

| The Britannia Tubular Bridge. | 115 |

| Victoria Tubular Bridge, Montreal. | 117 |

| The Clifton Bridge. | 122 |

| The Brooklyn Bridge. | 123 |

| The Forth Bridge. | 129 |

| The Thames Tunnel. | 143 |

| Boring machine used for the Mont Cenis Tunnel. | 149 |

| The entrance to the air-lock. | 155 |

| The boring machine used in the preliminary construction of the English Channel Tunnel. | 159 |

FIRST STEPS.

“I think I could make a better engine than that.”

“Do you? Well, some’ing’s wanted; hauling coal by horses is very expensive.”

“Ay, it is, and I think an engine could do it better.”

“Mr. Blackett’s second engine burst all to pieces; d’ye mind that?”

“How came that about?”

“Tommy Waters, who put it together, could not make it go, so he got a bit fractious and said she should move. He did some’ing to the safety-valve and she did begin to work, but then she burst all to pieces.”

“Ay, ay, but this one is an improvement.”

“It had need be. Even the third was a perfect plague.”

“What! you mean Mr. Blackett’s third engine?”

“Ay. It used to draw eight or nine truck loads at about a mile an hour, or a little less; but it often got cranky and stood still.”

“Stood still!”

“Ay; we thought she would never stick to the road, so we had a cogged wheel to work into a rack-work rail laid along the track, and somehow she was always getting off the rack-rail.”

“And now you find that the engine is heavy enough herself to grip the rail.”

“Ay, that was Will Hedley’s notion; he’s a viewer at the colliery. And it is a great improvement. Why, that third engine, I say, was a perfect nuisance. Chaps used to sing out to the driver: ‘How do you get on?’”

“‘Get on,’ sez he, ‘I don’t get on; I on’y get off!’”

“It was always goin’ wrong, and horses was always having to be got out to drag it along.”

“How did Hedley find out that a rack-rail was not needful?”

“Well, he had a framework put upon wheels and worked by windlasses which were geared to the wheels. Men were put to work these windlasses which set the wheels going; and, lo and behold, she moved! The wheels, though smooth, kept to the rails, though they were smooth also, and the framework went along without slipping. ‘Crikey!’ says Hedley, ‘no cogged wheels, no chains, no legs for me! We can do without ’em all. Smooth wheels will grip smooth rails.’ And he proved it too by several experiments.”

“Then Mr. Blackett had this engine built?”

“Ay, and it be, as you say, a great improvement. But that steam blowing off there, after it have done its work, frights the horses on the Wylam Road ter’ble, and makes it a perfect nuisance.”

“Has nothing been done to alter it?”

“Mr. Blackett has given orders to stop the engine when any horses comes along, and the men don’t like that because it loses time. He thinks he is going[11] to let the steam escape gradual like, by blowing it off into a cask first.”

“Umph! very wasteful.”

“Oh, ay; it be wasteful; and many a one about here sez of Mr. Blackett that a fool and his money are soon parted.”

“No,” said the first speaker, shaking his head thoughtfully, “Mr. Blackett is no fool. But I think I could build a better engine than that.”

The tone in which these words were uttered was not boastful, but quiet and thoughtful.

“You are Geordie Stephenson, the engine-wright of the Killingworth Collieries, ’beant you?”

“Ay; and we have to haul coal some miles to the Tyne where it can be shipped. So you do away with all rack-work rails and all cogged wheels, do you?”

“Ay, ay, Geordie, that’s so—smooth wheels on smooth rails.”

This conversation, imaginary though to some extent it be, yet embodies some important facts. Jonathan Foster, Mr. Blackett’s engine-wright, informed Mr. Samuel Smiles, who mentions the circumstance in his “Lives of the Engineers,” that George Stephenson “declared his conviction that a much more effective engine might be made, that should work more steadily and draw the load more effectively.”

Geordie had studied the steam-engine most diligently. Born at Wylam—some eight miles distant from Newcastle, about thirty years previously—he had become a fireman of a steam-engine and had been wont to take it to pieces in his leisure. He was now thinking over the subject of building a locomotive engine, and he decided to see what had already been accomplished. He would profit by the failures and successes of others. So he went over to Wylam to see Mr. Blackett’s engines, and to Coxlodge Colliery to see Mr. Blenkinsop’s from Leeds; and here again it is said, that after watching the machine haul sixteen locomotive waggons at a speed of about three miles an hour, he expressed the opinion that “he thought he could make a better engine than that, to go upon legs.”

A man named Brunton did actually take out a patent in 1813 for doing this. The legs were to work alternately, like a living creature’s. The idea which seems to have troubled the early inventors of the locomotive, was that smooth wheels would not grip smooth rails to haul along a load. And it was Blenkinsop of Leeds who took out a patent in 1811 for a rack-work rail into which a cog-wheel from his engine should work.

Thus William Hedley’s idea of trusting to the weight of the engine to grip the rails, and abolishing all the toothed wheels and legs and rack-work for this purpose on a fairly level rail, was the first great step toward making the locomotive a practicable success.

“PUFFING BILLY,” THE OLDEST LOCOMOTIVE ENGINE IN EXISTENCE.

(At present in South Kensington Museum.)

The idea that Stephenson invented the locomotive is a mistake. But just as James Watt improved the crude steam pumps and engines he found in existence, so George Stephenson of immortal memory developed and made practicable the locomotive. For, in spite of Hedley’s discovery or invention, all locomotives were partial failures until Stephenson took the matter in hand.

Nevertheless, William Hedley’s “Puffing Billy” must be regarded as one of the first practicable railway engines ever built. It is still to be seen in the South Kensington Museum, London. Patented in 1813, it began regular work at Wylam in that year, and continued in use until 1872. It was probably this engine which Stephenson saw when he said to Jonathan Foster that he could make a better, and it was no doubt the first to work by smooth wheels on smooth rails. Altogether it has been looked upon as the “father” of the enormous number of locomotives which have followed.

Mr. Blackett was a friend of Richard Trevithick; and among the various inventors and improvers of the locomotive engine Richard Trevithick, a tin-miner in Cornwall, must have a high place.

Trevithick was a pupil of Murdock, who was assistant of James Watt. Murdock had made a model successfully of a locomotive engine at Redruth. Others also had attempted the same thing. Savery had suggested something of the kind; Cugnot, a French engineer, built one in Paris about 1763; Oliver Evans, an American, made a steam carriage in 1772; William Symington, who did so much for the steamboat, constructed a model of one in 1784. So that many minds had been at work on the problem.

But Richard Trevithick was really the first Englishman who used a steam-engine on a railway. He had not much money and he persuaded his cousin, Andrew Vivian, to join him in the enterprise. In 1802 they took out a patent for a steam-engine to propel carriages.

But before this he had made a locomotive to travel along roads, and on Christmas Eve, 1801, the wonderful sight could have been seen of this machine carrying passengers for the first time. It is indeed believed to have been the first occasion on which passengers were conveyed by the agency of steam—the pioneer indeed of a mighty traffic.

The machine was taken to London and exhibited in certain streets, and at length, in 1808, it was shown on ground where now, curiously enough, the Euston Station of the London and North-Western Railway stands. Did any prevision of the extraordinary success of the locomotive flash across the engineer’s brain? Before the infant century had run its course what wonderful developments of the strange new machine were to be seen on that very spot!

Much interest was aroused by the exhibition of this machine, and Sir Humphrey Davy, a fellow Cornishman, is reported to have written to a friend—“I shall soon hope to hear that the roads of England are the haunts of Captain Trevithick’s dragons—a characteristic name.”

His letter tends to show that the idea then was that the engine should run on the public roads, and not on a specially prepared track like a railway. Had not this idea been modified, and the principle of a railroad adopted, it is hardly too much to say that the extraordinary development of the locomotive would not have followed.

Trevithick’s first engine appears to have burst. At all events, in the year 1803 or 1804, he built, and began to run, a locomotive on a horse tramway in South Wales. It appears that he had been employed to build a forge-engine here, and thus the opportunity was presented for the trial of a machine to haul along minerals. This, it is believed, was the first railway locomotive, and its builder was Richard Trevithick.

The trial, however, was not very successful. Trevithick’s engine was too heavy for the tramway on which [17] it ran, and the proprietors were not prepared to put down a stronger road. Furthermore, it once alarmed the good folk, unused then to railway accidents, by actually running off its rail, though only travelling at about four or five miles an hour. It had to be ignominiously brought home by horses. That settled the matter. It became a pumping engine, and as such answered very well.

In this locomotive, however, it should be noted Trevithick employed a device which, a quarter of a century later, Stephenson made so valuable that we might call it the very life-blood of the Locomotive. We mean the device of turning the waste steam into the funnel (after it has done its work by driving the piston), and thus forcing a furnace draught and increasing the fire. Stephenson, however, sent the steam through a small nozzled pipe which made of it a veritable steam-blast, while Trevithick, apparently, simply discharged the steam into the chimney.

Disgusted it would seem by the failure, the inventor turned his attention to other things. Trevithick appears to have lingered on the very brink of success, and then turned aside. Another effort and he might have burst the barrier. But it was not to be; though if any one man deserve the title, Inventor of the Locomotive, that man is the Cornish genius Trevithick. Readers who may desire fuller information of Trevithick and his inventions will find it in his “Life” by Francis Trevithick, C.E., published in 1872.

It must be borne in mind that Stephenson found the imaginary hindrance that smooth wheels would not grip smooth rails, cleared away for him by Hedley’s experiment, whereas Trevithick had to contend against this difficulty. He strove to conquer it by roughing the circumference of his wheels by projecting bolts, so that they might grip in that way. That is, his patent provided for it, if he did not actually carry out the plan.

It is very significant that this imaginary fear should[18] have hindered the development of the locomotive. The idea seems to have prevailed that, no matter how powerful the engine, it could not haul along very heavy loads unless special provision were made for its “bite” or grip of the rails. Another difficulty with which Trevithick had to contend was one of cost. It is said that one of his experiments failed in London for that reason. This was apparently the locomotive for roads, as distinct from the locomotive for rails. A machine may be an academic triumph, but the question of cost must be met if the machine is to become a commercial and industrial success.

Mr. Blenkinsop of Leeds then took out his patent in 1811 for a rack-work rail and cogged wheel; but before this Mr. Blackett of Wylam had obtained a plan of Trevithick’s engine and had one constructed. He had met Trevithick at London, and it was as early as 1804 that he obtained the plan. The engines, therefore, of Mr. Blackett which Stephenson saw, came, so to speak, in direct line from Trevithick, except that Mr. Blackett’s second engine was a combination of Blenkinsop’s and Trevithick’s.

Some progress was made, but when on that memorable day George Stephenson, the engine-wright of Killingworth, said, “I think I could build a better engine than that,” no very effective or economical working locomotive was in existence.

Back therefore went George Stephenson to his home. He had seen what others had done, and with his knowledge of machinery and his love for engine work he would now try what he could do.

Would he succeed?

GLANCING BACKWARDS AND STRUGGLING FORWARDS.

“My lord, will you spend the money to build a Travelling Engine?”

“Why? what would it do?”

“Haul coals to the Tyne, my lord. The present system of hauling by horses is very costly.”

“It is. But how would you manage it by a Travelling Engine?” Thereupon George Stephenson the engine-wright proceeded to explain.

In some such manner as this we can imagine that Stephenson opened up the subject to Lord Ravensworth, the chief partner in the Killingworth Colliery; and he won his lordship over.

Stephenson had already improved the colliery engines, and Lord Ravensworth had formed a high opinion of his abilities. So after consideration he gave the required consent.

Now, let us endeavour to imagine the position. The steam engine, of which the locomotive is one form, had been invented years before. The Marquis of Worcester made something of a steam engine which apparently was working at Vauxhall, South-west London, in 1656. It is said that he raised water forty feet, and by this we may infer that his apparatus was a steam-pump. He describes it in his work “Century of Inventions,” about 1655, and he is generally accredited with being the inventor of the steam engine. It was, however, a very primitive affair, the boiler being the same vessel as that in which the steam accomplished its work.

Captain Savery took the next step. He was the first to obtain a patent for applying steam power to machinery. This was in 1698, and he used a boiler distinct from the vessel where the steam was to exert[20] its power. Savery’s engines appear to have been used to drain mines.

His engines acted in this way—the steam was condensed in a vessel and produced a vacuum which raised the water; then the steam pressing upon it raised it further in another receptacle.

An obvious improvement was the introduction of the piston. This was Papin’s idea, and he used it first in 1690. Six years later an engine was constructed by Savery, Newcomen (a Devonshire man), and Cawley, in which the “beam” was introduced, and also the ideas of a distinct boiler separate from a cylinder in which worked a piston. This machine was in operation for about seventy years. The beam worked on an axle in its centre—something like a child’s “see-saw,” and one end being attached to the piston moving in the cylinder, it was worked up and down, the other end of the beam being fastened to the pump-rod, which was thus alternately raised and depressed.

The upward movement of the piston having been effected by a rush of steam from the boiler upon its head, the steam was cut off and cold water run in upon it from a cistern. The steam was thus condensed by the water and a vacuum caused, and the piston was pressed down by the weight of the atmosphere—of course dragging down its end of the beam, and raising the pump-rod. The steam was then turned on again and pushed up the piston, and consequently the end of the beam also. Thus the engine continued to work, the turning of the cocks to admit steam and water being performed by an attendant. The engine was, however, made self-acting in this respect, and Smeaton improved this form of engine greatly. The beam is still used in engines for pumping.

Nevertheless, improved though it became, it was still clumsy and almost impracticable. It was the genius of James Watt which changed it from a slow, awkward, cumbrous affair into a most powerful, practicable, and useful machine.

His great improvements briefly were these: he condensed the steam in a separate vessel from the cylinder, and thus avoided cooling it and the consequent loss of steam power; secondly, he used the steam to push back the piston as well as to push it forward (this is called the “double-acting engine,” and is now always used); thirdly, he introduced the principle of using the steam expansively, causing economy in working; and fourthly, he enabled a change to be made of the up and down motion of the piston into a circular motion by the introduction of the crank.

The use of the steam expansively is to stop its rush to the cylinder when the piston has only partially accomplished its stroke, leaving the remainder of the[22] stroke to be driven by the expansion of the steam. In early engines the steam was admitted by conical valves, worked by a rod from the beam. Murdock, we may add in parenthesis, is believed to have invented the slide-valve which came into use as locomotives were introduced, and of which there are now numerous forms. The valve is usually worked by an “eccentric” rod on the shaft of the engine.

Watt was the author of many other inventions and improvements of the steam engine. Indeed, although Savery and Newcomen and others are entitled to great praise, it was Watt who gave it life, so to speak, and made it, in principle and essence, very much that which we now possess. There have, indeed, been improvements as to the boiler, as to expansive working, and in various details, since his day; but, apart from the distinctive forms of the locomotive and the marine engine, the machine as a whole is in principle much as Watt left it.

The centre of all things in a steam engine is usually the cylinder. Here the piston is moved backward and forward, and thence gives motion as required to other parts of the machine.

The cylinder is in fact an air-tight, round box, fitted with a close-fitting, round plate of metal, to which is fixed the piston-rod. Now, it must be obvious that if the steam be admitted at one end of the cylinder it will, as it rushes in, push the metal plate and the piston outward, and if this steam be cut off, and the steam admitted to the other end of the cylinder, it will push the metal plate and piston back again.

But what is to be done with the steam after it has accomplished its work? It may be permitted to spurt out into the air, or into a separate vessel, where it may be condensed. In the locomotive, under Stephenson’s able handling, this escape of steam was created into a steam-blast in the chimney to stimulate the fire. In compound and triple-expansion engines the steam is used—or expanded, it is called—in two or three[23] cylinders respectively. When steam is condensed, it may be returned to the boiler as water.

It was the repairing of a Newcomen engine that seems to have started Watt on his inventions and improvements of the steam engine. He was then a mathematical instrument maker at Glasgow. As a boy he had suffered from poor health, but had been very observant and studious; and it is said that his aunt chided him on one occasion for wasting time in playing with her tea-kettle. He would watch the steam jetting from its spout, and would count the water-drops into which the steam would condense when he held a cup over the white cloud.

Delicate though he was in health, he studied much, and came, indeed, to make many other articles besides mathematical instruments. When, therefore, the Newcomen engine needed repair, it was not unnatural that it should be brought to him. It appears to have been a working model used at Glasgow University. He soon repaired the machine; but, in examining it, he became possessed with the idea that it was very defective, and he pondered long over the problem—How it might be improved. What was wanting in it? How could the steam be condensed without cooling the cylinder?

Suddenly, one day, so the story goes, the idea struck him, when loitering across the common with bent brows, that if steam were elastic, it would spurt into any vessel empty of air. Impatiently, he hastened home to try the experiment. He connected the cylinder of an engine with a separate vessel, in which the air was exhausted, and found that his idea was correct; the steam did rush into it. Consequently the steam could be condensed in a separate vessel, and the heat of the cylinder maintained and the loss of power prevented. This invention seems simple enough; yet it increased the power of an engine threefold, and is at the root of Watt’s fame. We must remember that the inventions which in process of time may[24] appear the simplest and the most commonplace, may be the most difficult to originate. And it may fairly be urged—If it were so very simple, and so very obvious, why was it not invented before? The supposition is that in those days it was not so simple. It is possible that the great elasticity of steam was not sufficiently understood. In any case, the discovery and its application are regarded as his greatest invention.

Yet ten years elapsed before he constructed a real working steam engine, and so great we may suppose were the difficulties he encountered, including poorness of health, that once he is reported to have exclaimed: “Of all things in the world, there is nothing so foolish as inventing.”

But a brilliant triumph succeeded. Eventually Watt became partner with Mr. Matthew Boulton, and the firm of Boulton & Watt manufactured the engine at Soho Ironworks, Birmingham. Mining proprietors soon discovered the value of the new machine, and Newcomen’s engine was superseded for pumping.

Watt continued to improve the machine, and together with Boulton also greatly improved the workmanship of constructing engines and machinery. In a patent taken out in 1784, he “described a steam locomotive”; but for some reason he did not prosecute the idea. It is possible that the notion of building a special road for it to run upon did not occur to him, or appear very practicable.

His work was done, and it was a great work; but it was left for others to develop the steam engine into forms for hauling carriages on land or propelling ships upon the sea. Trevithick, Stephenson, and others did the one; Symington, Bell, and others did the second. Watt died in 1819, and though so delicate in youth, he lived to his eighty-fourth year.

The steam engine, therefore, as Watt left it, was practically as Stephenson came to know it. He would be acquainted with it chiefly as a pumping machine.[25] But he saw what others had done to adopt it as a locomotive, and he now set to work.

Stephenson’s first engine did not differ very materially from some of those which had preceded it. He was, so to speak, feeling his way. The machine had a round, wrought-iron boiler, eight feet long, with two upright cylinders placed on the top of it. At the end of the pistons from the cylinders were cross-rods connected with cogged wheels below by other rods. These cogged wheels gave motion to the wheels running on the rails by cogs not very far from the axles. Stephenson abandoned the cogged rail, and adopted smooth wheels and smooth rails; but he did not connect the driving-wheel direct with the piston, the intervening cogged wheels being thought necessary to unite the power of the two cylinders.

In adopting the principle of smooth wheels on smooth rails, it is said that Stephenson proved by experiment that the arrangement would work satisfactorily. Mr. Smiles writes that Robert Stephenson informed him, “That his father caused a number of workmen to mount upon the wheels of a waggon moderately loaded, and throw their entire weight upon the spokes on one side, when he found that the waggon could thus be easily propelled forward without the wheels slipping. This, together with other experiments, satisfied him of the expediency of adopting smooth wheels on his engine, and it was so finished accordingly.” Thus it may be said that this obstacle—imaginary though it largely proved to be—was cleared away from Stephenson’s first engine.

Ten months were occupied in building the machine, and at last came the day of its trial. This was the 25th of July, 1814. Would it work?

Jolting and jerking along, it did work, hauling eight carriages at a speed of about four or six miles an hour—as fast as a brisk man could walk. Then came the question—Would it prove more economical than horse-power?

Calculations therefore were made, and after a time it was found that “Blucher” as the engine was called, though we believe its real name was “My Lord,” was about as expensive as horse-power.

The locomotive needed something more, some magic touch to render it less clumsy and more effective. What was it?

Then came the first great practicable improvement after the smooth wheels on smooth rails. It was the steam-blast in the funnel, by which the draught in the furnace was greatly increased. Indeed, the faster the engine ran the more furiously the fire would burn, the more rapid would be the production of steam, and the greater the power of the engine.

At first Stephenson had allowed his waste steam from the cylinders to blow off into the air. So great was the nuisance caused by this arrangement that a law-suit was threatened if it were not abated.

What was to be done with that troublesome waste steam? Now, whether Stephenson originated the idea or adapted what Trevithick had done, we cannot say, but at all events he achieved the object, wherever he gained the idea. He turned his exhaust steam through a pipe into the funnel, and at a stroke increased the power of his engine two-fold.

But that expedient was not alone. Stephenson had watched the working of “Blucher” to some purpose, and he decided to build another engine with improvements.

The cumbersome cog-wheels must go; they complicated the machine terribly, and prevented its practicability. Therefore in his second engine he introduced direct connection between the pistons and the wheels. There were a couple of upright cylinders as before, with cross-rods attached to the piston-ends, and connecting rods from the end of each cross-rod, reaching down to the wheels. But to overcome the difficulty of one wheel being at some time higher than the other on the poorly constructed railway of that period, a joint was[27] introduced in the cross-rod, so that if, perchance, the two wheels should not be always on exactly the same level, no undue strain should be placed on the cross-rod. Furthermore, the two pairs of wheels were combined first by a chain, but afterwards by connecting rods. This may be called the locomotive of 1815, the year in which the patent was taken out.

The engine accomplished its work more satisfactorily than before, and was placed daily on the rails to haul coal from the mine to the shipping point. But still its economy over horse-power was not so great as to cause its wide adoption. And it was still little better, if anything, than a mere coal haul.

Nevertheless Stephenson persevered. He was appointed engineer to the Stockton and Darlington Railway—an enterprise largely promoted by Mr.[28] Edward Pease. It was opened on the 27th of September, 1825, and a local paper writes as follows:—

“The signal being given, the engine started off with this immense train of carriages, and such was its velocity, that in some parts the speed was frequently 12 miles an hour; and at that time the number of passengers was counted to be 450, which, together with the coals, merchandise, and carriages, would amount to near 90 tons. The engine, with its load, arrived at Darlington, a distance of 8¾ miles, in 65 minutes. The 6 waggons loaded with coals, intended for Darlington, were then left behind; and obtaining a fresh supply of water, and arranging the procession to accommodate a band of music and numerous passengers from Darlington, the engine set off again, and arrived at Stockton in 3 hours and 7 minutes, including stoppages, the distance being nearly 12 miles.”

Stephenson became a partner in a business for constructing locomotives at Newcastle, and three engines were made for the Stockton and Darlington Railway. Nevertheless they appear to have been used chiefly if not almost entirely for hauling coal; for the passenger-coach called the Experiment was hauled by a horse, and the journey occupied about two hours.

The locomotive was not even yet a brilliant success over horse-power. What was to be the next step?

FIFTEEN MILES AN HOUR.

Five hundred pounds for the best locomotive engine!

So ran the announcement one day in the year 1829. The Liverpool and Manchester Railway was nearly completed, but yet the directors had not[29] fully decided what power they would employ to haul along their waggons.

Horse-power had at length been finally abandoned, and numbers of schemes had been poured in upon the managers. But the contest seemed at last to resolve itself chiefly into a rivalry between fixed and locomotive engines. Principally, if not entirely, swayed however by the arguments of George Stephenson, the directors yielded to the hint of a Mr. Harrison, and offered a £500 prize.

The engine was to satisfy certain conditions. Its weight was not to be above six tons; it was to burn its own smoke, haul twenty tons at a rate of ten miles an hour, be furnished with two safety valves, rest on springs and on six wheels, while its steam pressure must not be more than fifty lbs. to the square inch. The cost was not to exceed £550.

Stephenson, who was the engineer of the Railway, decided to compete. He was now in a very different position from that which he occupied when he built his second locomotive in 1815. His appointment as engineer to the Stockton and Darlington Railway had greatly aided his advancement, and when it was decided to build a railway between the two busy cities of Manchester and Liverpool it was not unnatural that he should take part in the undertaking.

The idea of constructing rail, or tram ways, was not new. Railways of some kind were used in England about two hundred years before, that is, about the beginning of the seventeenth century. Thus Roger North writes:—“The manner of the carriage is by laying rails of timber from the colliery to the river, exactly straight and parallel; and bulky carts are made with four rollers fitting those rails, whereby the carriage is so easy that one horse will draw down four or five chaldron of coals, and is an immense benefit to the coal merchants.”

It is said that the word tramway is derived from tram, which was wont to mean a beam of timber and[30] also a waggon. In any case, such rough ways were introduced in mining districts, for, as may be readily believed, one horse could draw twenty times the load upon them that it could on an ordinary road.

The old ways were first made of wood, then of wood faced with iron, then altogether of iron.

Now, in making his railway between Liverpool and Manchester, Stephenson had many difficulties to encounter. He decided that the line should be as direct as possible. But to accomplish this, he would have to pierce hills, build embankments, raise viaducts, and, hardest of all, construct a firm causeway across a treacherous bog called Chat Moss.

“He will never do it,” said some of the most famous engineers of the day. “It is impossible!”

Impossible it certainly seemed to be. Chat Moss was like a sponge, and how was an engineer to build a solid road for heavy trains over four miles of soppy sponge! A person could not trust himself upon it in safety, and when men did venture, they fastened flat boards to their feet, something after the fashion of snow-shoes, and floundered along upon them.

Stephenson began by taking the levels of the Moss in a similar manner. Boards were placed upon the spongy moss, and a footpath of heather followed. Then came a temporary railroad. On this ran the trucks containing the material for a permanent path, which were pushed by boys who learned to trot along easily on the narrow rails.

Drains were dug on either side of the proposed road, and tar-barrels covered with clay were fitted into a sewer underneath the line in the middle of the Moss. Heather, hurdles, tree branches, etc., were spread on the surface, and in some parts an embankment of dry moss itself was laid down. Ton after ton of it disappeared until the directors became alarmed, and the desperate expedient of abandoning the works was considered.

But Stephenson was an Englishman out and out. He never knew when he was beaten. “Keep on[31] filling,” he ordered; and in spite of all criticism and all alarm, he kept his hundreds of navvies hard at work, pouring in load after load of dry turf.

It must be borne in mind, however, that Stephenson did not continue blindly at his task. He had good reason for what he did. His persistence was a patient, intelligent perseverance, and not a stupid obstinacy. His main arguments seem to have been two. He judged that if he constructed a sufficiently wide road, it would float on the moss, even as ice or a raft of wood floats on water and bears heavy weights; and secondly, he seems to have been animated by the idea, that, if necessary, he could pour in enough solid or fairly solid stuff to reach the bottom and rise up to the surface in a hard mass.

Both ideas seem to have been realised in different parts of the bog. Joy took the place of despair, and triumph exulted over discouragement, as at length the solid mass appeared through the surface. Furthermore, the expense was found to be none so costly after all. No doubt any quantity of turf could be obtained from the surrounding parts of the Moss and dried.

At another part of the railway called Parr Moss an embankment about a mile and a-half was formed by pouring into it stone and clay from a “cutting” in the neighbourhood. In some places twenty-five feet of earth was thus concealed beneath the Moss. The eye of the engineer had as it were pierced through the bog and seen that his solid bank was steadily being built up there.

Before, however, the road across Chat Moss was fairly opened, the trial of locomotives for the prize of £500 had taken place. The fateful day was the 1st day of October, 1829, and the competition was held at Rainhill. A grand stand was erected, and the side of the railway was crowded. Thousands of spectators were present. The future of the locomotive was to be decided on this momentous occasion.

Now, hitherto the difficulty in the locomotive had[32] been to supply a steady and sufficient supply of steam to work the engine quickly and attain high speed and power. Partly, this had been accomplished by Stephenson’s device of the steam-blast in the funnel. But something more was needed.

That requirement was found in the tubular boiler. If the long locomotive boiler were pierced with tubes from end to end, it is clear that the amount of heating surface offered to the action of the fire would be greatly increased. It was this idea which was utilised in the “Rocket,” the engine with which Stephenson competed at Rainhill, and utilised more perfectly than ever before.

Trevithick himself seems to have invented something of the kind, and M. Seguin, the engineer of the St. Etienne and Lyons Railway utilised a similar method. But Henry Booth, the secretary of the railway which Stephenson was then building, invented a tubular boiler without, it is said, knowing anything of Seguin’s plan, and Stephenson who had already experimented in the same direction, adopted Booth’s method.

At first it was a failure. The boiler, fitted with tubes through which the hot air could pass, leaked disastrously, and Stephenson’s son, Robert, wrote to his father in despair. But again George said “persevere,” and he suggested a plan for conquering the difficulty. Again, it was a simple, but as the event proved, an effective plan.

The copper tubes were merely to be fitted tightly to holes bored in the boiler and soldered in. The heat caused the copper to expand and the result was a very strong and water-tight boiler. There were twenty-five of these tubes, each three inches in diameter, and placed in the lower portion of the boiler, leading from the furnace to the funnel. Water also surrounded the furnace. Further, the nozzles of the steam-blast pipes were contracted so as to increase the power of the blast, and consequently raise the strength of the draught to the fire.

The cylinders were not placed at the top of the boiler, but at the sides in a slanting direction, one end being about level with the boiler roof. They occupied a position mid-way between the old situation upright on the roof and their present position below, or at the lower portion. The pistons acted directly on the driving wheels by means of a connecting rod, and the entire weight of the engine with water supply was but 4½ tons.

On the day of trial only four engines competed. Many had been constructed, but either were not completed in time, or for various reasons could not be exhibited. The famous four were:—The “Novelty” by Messrs. Braithwaite and Ericsson; The “Rocket” by Messrs. R. Stephenson & Co.; The “Perseverance” by Mr. Burstall; and The “Sanspareil” by Mr. Timothy Hackworth. Each engine seems to have run separately, and the length of the course was two miles. The test was that the engine should run thirty miles, backwards and forwards, on the two mile level course, at not less than ten miles an hour, dragging three times its own weight.

The “Novelty” at first appears to have beaten the “Rocket,” for she ran at times at the rate of twenty-four miles an hour; while the first trip of the “Rocket” covered a dozen miles in fifty-three minutes. The engineers of the “Novelty” used bellows to force the fire, but on the second day these bellows gave way, and the engine could not do its work. The boiler of the “Sanspareil” also showed defects, but Stephenson’s “Rocket” calmly stood the strain. Practicable as usual, Stephenson’s work was as good in its results, nay, even better than before, for he hooked the “Rocket” to a carriage load of thirty people, and rushed them along at the then surprising speed of between twenty-four to thirty miles an hour. Mr. Burstall’s “Perseverance” could not cover more than six miles an hour.

The competitions continued, but the “Novelty,”[36] although running at the rate of twenty-four and even twenty-eight miles an hour, broke down again and yet again; its boiler plates appear to have gone wrong on one occasion; while the “Sanspareil” also failed, and furthermore blew a good deal of its fuel into the air because of the arrangement of its steam-blast.

But the more the “Rocket” was tried, the more practicable and reliable the engine appeared to be. On the 8th of October it gained a speed of 29 miles an hour, its steam pressure being about 50 lbs. to the square inch, and its average speed was fifteen miles an hour—that is, five miles an hour over the conditions required. These results appear to have been accomplished with a weight of waggons of thirteen tons behind it. When detached it ran at the rate of thirty-five miles an hour.

In short, the “Rocket” was the only locomotive which fulfilled all the conditions specified for the competition, and the prize was duly awarded to Stephenson and Booth.

The battle of the locomotive was won. Men could see that the machine was feasible and practicable; that it was a new force with immense possibilities before it.

How have those possibilities been realised?

A MARVEL OF MECHANISM.

“The time is coming when it will be cheaper for a working man to travel on a railway than to walk on foot.”

So prophesied George Stephenson some few years before his successful competition at Rainhill; and by his success on that fateful day, he had brought the time appreciably nearer. The directors of the Liverpool[37] and Manchester Railway no longer debated as to what form of traction they should adopt.

But Stephenson did not rest on his laurels. Every new engine showed some improvement. The “Arrow” sped over Chat Moss at about 27 miles an hour, on the occasion of the first complete journey along the line, on the 14th of June, 1830; and when, on the public opening of the railway on the 15th of September, 1830, Mr. William Huskisson, M.P., was unhappily knocked down by the “Rocket,” George Stephenson himself took the maimed body in the “Northumbrian,” fifteen miles in twenty-five minutes—that is, he drove the engine at the speed of thirty-six miles an hour.

The sad death of Mr. Huskisson has often been referred to, but we may tell the story again, following the account given by Mr. Smiles, who had the advantage of the assistance of Robert Stephenson in the preparation of his biography.

The engines it appears halted at Parkside, some seventeen miles from Liverpool, to obtain water. The “Northumbrian,” with a carriage containing the Duke of Wellington and some friends, stood on one line, so that all the trains might pass him in review on the other. Mr. Huskisson had descended from the carriage and was standing on the rail on which the “Rocket” was rapidly approaching. There had been some coolness between the Duke and Mr. Huskisson, but at this time the Duke extended his hand and Mr. Huskisson hurried to grasp it, when the bystanders cried “Get in! get in.”

Mr. Huskisson became flurried and endeavoured to go round the carriage door which was open and hung over the rail; but while doing this, the “Rocket” struck him and he fell, his leg being doubled over the rail and immediately crushed. Unfortunately he died that evening at Eccles Parsonage.

This sad event cast a gloom over the otherwise rejoicing day; but the wonderful speed at which the wounded man was conveyed, proved a marvellous object lesson as to what the locomotive could accomplish.

In the “Planet,” put upon the line shortly after the opening, the cylinders were placed horizontally and within the fire box. The engine drew eighty tons from Liverpool to Manchester against a strong wind in two and a-half hours, while on another occasion with a company of voters, it sped from Manchester to Liverpool, thirty-one miles, in an hour. But next year the “Samson,” which was still further improved, and the wheels of which were coupled so as to secure greater grip on the rails, hauled 150 tons at twenty miles an hour with a smaller consumption of fuel.

The locomotive had now become one of the wonders of the world. Since then its speed has been doubled. But all the improvements (with possibly one exception—that of the compound cylinder which is at present only partially in use) have been more in details than in principles. Thus the 70 or 80 ton express engine, which covers mile after mile at the rate of a mile a minute without a wheeze or a groan, is not very different essentially from George Stephenson’s locomotives, though its steam pressure is very much higher.

There are, for instance, the multitubular boiler, the furnace surrounded by water and communicating with the boiler, the horizontal cylinders acting directly on the driving wheels, and the steam-blast by which the waste steam is spouted up the chimney, creating a draught in the furnace.

These may be regarded as the more important of the essential principles, although there is diversity of details, more especially for the different work required. But the steam pressure is now much greater. Let us glance at a typical English locomotive. You might not think it, but the machine has about five thousand different parts, all put together as Robert Stephenson said “as carefully as a watch.”

At first sight you will probably not see the cylinders. The tendency in many engines now seems to be to place them inside the wheels, for it is urged that the placing[39] of the heavier parts of the mechanism near to the centre lessens oscillation, and protects the machinery more effectually. Against this, it is said that the placing of the cylinders in that position increases the cost and the complication of the driving axle, and renders the pistons and valves more inaccessible for the purposes of repair. Both forms have their advocates, and the outside-cylinder form may be seen on the London and South-Western and some other railways, while the inside may be seen on the North-Western and others.

The boiler is of course the long, round body of the locomotive, and in English machines it is placed on a strong plate frame. Then as to the driving-wheels. Express engines, such as the splendid “eight-feet singles” of the Great Northern, have often, as the name implies, but one large driving-wheel on either side, and for great speeds this form is held to possess certain advantages. Certainly the performances of Mr. Patrick Stirling’s expresses would indicate that this is the case.

With steam raising the safety valve at a pressure of 140 lbs. to the square inch, the engines will whisk a score of carriages out of King’s Cross up the northern height of London at forty miles an hour, and then without a stop rush on to Grantham at near sixty. Standing on the platform at King’s Cross, with a large part of the immense driving-wheel hidden below you as it rests on the rail, you do not realise its tremendous size. Yet, let the engine-driver open the throttle, as it is called—that is, turn on the steam to the cylinders—and that huge wheel will revolve, and with its neighbour on the other side, haul after them that heavy train of carriages, and, gathering speed as they go, they will soon be rushing up the incline at forty miles an hour, and then on at sixty. It is a marvel of mechanism!

But then the compound engines that Mr. F. W. Webb, the engineer of the North-Western, builds for that Company can also perform remarkable things.[40] The compound is the great modern improvement (some engineers might doubt whether improvement be the correct word) in the locomotive, effecting, it is said, an economy of from ten to fifteen per cent. in fuel. Now the compounding principle has been developed to such an extent in marine steam engines that it revolutionised steam navigation. But the application of the principle has not been so great in the case of the locomotive.

Briefly, the principle is this—the steam is sent out from the boiler at a high pressure, say 160 to 180 lbs. to the square inch, and is used in one or in a pair of high-pressure cylinders, and then used again, by means of its expanding power, in a larger, low-pressure cylinder. Mr. John Nicholson, of the Great Eastern Railway, suggested a compound locomotive before even the compound marine engine had been made, and his design was successful; but in 1881 Mr. Webb, of the North-Western, patented a compound locomotive, with two small high-pressure, and one large low-pressure cylinders, the latter twenty-six inches in diameter. Placed between the front wheels, the bright boss of this cylinder may be seen in shining steel as it flies over the rails.

The argument is that the compound burns less fuel and is more powerful than a non-compound of the same weight; but against this is launched the objection that the compound is more expensive to build, to repair, and to maintain. Still further it is argued, that a fast-speeding locomotive has not the time in its hurrying life to expand its steam in the tick of time between each stroke of the piston.[41]

THE COMPOUND LOCOMOTIVE “GREATER BRITAIN.”

By kind permission of Mr. F. W. Webb, L. & N. W. Railway.

Mr. Worsdell’s compounds on the North-Eastern[42] Railway have but two cylinders, one high and the other low-pressure. The one is eighteen and the other twenty-six inches across. Instead of the steam alternating between the two cylinders, it all passes first to the high-pressure and then, through a pipe in the smoke-box, to the larger low-pressure cylinder. These [43]locomotives, it is said, are not under the objection alleged against the other compounds—viz., that they have more parts, and are more costly to build and maintain. Yet it is claimed for them that they are more economical and more powerful than non-compounds.

When doctors disagree who shall decide? The cost or speed might decide; but at present it seems doubtful on which side the balance does really fall. Engines of the three types have done splendid work. A Worsdell compound, built by Mr. Worsdell, of the North-Eastern Railway, is reported to have rushed down the incline to Berwick one day at seventy-six miles an hour for some miles at a time. Then the “Greater Britain,” a massive North-Western compound engine, turned out at the Crewe works in 1891, and weighing seventy-five tons, can whirl along with ease a heavy twenty-five coach express at an average of over fifty miles an hour, with a comparatively small consumption of fuel.

This locomotive was described in the Engineer newspaper as the most remarkable that had been built in England for several years. Its axle bearings are of great length, and its parts are very substantial, so that it ought to keep out of the repairing shops for long spells of time. It was specially planned for both fast and heavy passenger traffic to Scotland, and its work on its trial trip was so good that it was confidently expected it would answer expectations. In working, the engine has been found to develop great speed and power, easily running at over fifty miles an hour with what is called a double train—viz., twenty-five coaches, behind it. Indeed, it has run at fifty-five miles with this heavy train. Its stated speed ranges from thirty to fifty-five miles an hour, with a low consumption of fuel.

This last is a matter of very great importance to engineers and railway directors; and when we state that, according to Mr. Bowen Cooke, the North-Western[44] engines altogether burn 3095 tons of coal per day, any small saving per hour would be eagerly welcomed.

Now, it is claimed that the compounds have consumed about six pounds of coal per mile less than others on the same work, and that they also haul along loads which would require two of the other type. If so, the saving in the North-Western coal-bill must be enormous.

A great feature in this engine is a combustion chamber placed within the barrel of the boiler. This chamber catches all the gases from the furnace, and causes the heat generated by them to be used to the utmost for the production of steam. Though heavier than any engine previously built, yet it is so made that no greater weight than usual rests upon any of the[45] wheels, thus throwing no extra strain on the railway or the bridges. The two couples of driving-wheels are placed before the furnace, and an additional couple of small wheels behind the furnace, and beneath the foot-plate where the driver and fireman stand. The weight therefore is evenly distributed, with another pair of wheels to bear the burden. The front wheels are fitted with the radial axle-box patented by Mr. Webb, so that, although the engine is of great length, yet it can speed round curves with perfect safety.

Yet this engine, though one of the most remarkable developments of the locomotive, is in essence and in principle but very like the “Rocket.” The difference lies in its innumerable details, exhibiting so much engineering skill and ingenuity, in the compound cylinders, in higher pressure steam, and in its marvellous power and speed combined.

On the other hand, the Great Northern runs daily from Grantham to London at fifty-three and fifty-four miles an hour average; while it was reported in the Engineer of the 10th of March, 1888, that a Great Northern train from Manchester to London, when running from Grantham to London, covered one mile in forty-six seconds, that is, at the rate of seventy-eight and a-quarter miles an hour, and two miles following each other were run in forty-seven seconds each, that is, seventy-six miles an hour. We doubt, indeed, if any railway in the world can show regular faster daily running than some of the Great Northern expresses between London and Grantham. The average speed of their Manchester train over this ground is slightly over fifty-four miles an hour. Then there are the Great Western expresses, the “Dutchman” and the “Zulu,” at only slightly less speeds, to say nothing of the fine performances of the Midland. We may take it, therefore, that the compound locomotives, excellent as their work has been, have not really beaten their rivals in point of speed.

Compounds are used largely on the North-Western,[46] the Great Eastern, and the North-Eastern, and should they prove to be really more economical in working, while maintaining at least equal power and speed with their rivals, we have no doubt but that they will prevail.

A MILE A MINUTE.

“The express is to be quickened, my lord. Mr. Thompson, the general manager, has given instructions to that effect.”

So spoke the station master at Carlisle, on the 17th of March, 1894, to Lord Rosebery.

His lordship had very recently been appointed Prime Minister, and was on his way to Edinburgh to deliver a great public speech. The train, presumably, was late, or he, through stress of business probably, had left too little margin of time. However, by the instructions of Mr. Thompson, the general manager of the Caledonian Railway, the express was accelerated, and it rushed over 101 miles in 105 minutes, one of the quickest locomotive runs, we imagine, that have ever been recorded. The train arrived fifteen minutes before it was due, and Lord Rosebery was enabled to keep his engagement.

This run was approximately at the rate of a mile a minute, and maintained for an hour and three-quarters. Only some two years or so previously a somewhat similar run was made. An officer of the Guards found that he had lost the south-going mail train at Stirling. He had been on leave in Scotland, and was bound to report himself in London next morning.

What was he to do? Did he sit down and moan, or fly to the telegraph office and endeavour to excuse himself? Not he. He promptly engaged a special[47] train, which flying over the metals, actually caught the mail at Carlisle, having covered 118 miles in 126 minutes; that is, again, approximately a mile a minute, and maintained for slightly over two hours.

Now, in order to attain high average speed, some parts of the journey, say very easy inclines or levels, must be covered at a much higher rate. Thus, to obtain an average of fifty-two miles an hour—which is probably the regular average of our best English expresses—the pace will most likely be sometimes at the rate of seventy, or it may be seventy-six, miles per hour.

The United States have claimed to run the fastest regular train. This is the “Empire State Express” of the New York Central, which bursts away from New York to Buffalo, a trip of 140 miles, at the average rate of 52-12/100 miles per hour, but running eighty miles at the rate of 56¾ miles an hour. It is also said that, in August, 1891, a train on the New York portion of the Reading road ran a mile in less than forty seconds, and covered a dozen miles at an average of barely 43½ seconds per mile.

English expresses could certainly accomplish these average speeds, but the fact is very high speeds do not pay. They wear everything to pieces. Then there is the coal consumption. American railway engineers—according to the Engineer newspaper—“seem to be unable to get on with less than 100 lbs. per square foot (of fire grate area) as a minimum;” while, from the same paper, we learn that the average rate of burning of Mr. Webb’s remarkable North-Western engine, the “Greater Britain,” was but “a little over seventy-three lbs. per square foot per hour,” or, altogether, 1500 lbs. per hour.

The rails also are greatly worn by continuous high speeds. Engineers have been equal to this difficulty, and rails are now made of steel, and even steel sleepers are constructed on which the rails repose. But still the wear and tear, especially to engines, of continuous[48] high speeds, is very great. The reason why the famous “Race to Edinburgh” was stopped was doubtless because of the needless wear and tear. Surely an average of fifty to fifty-two miles an hour is fast enough for all ordinary purposes. If greater speed can be obtained without too great a cost, well and good; but if not, the public must be content.

Nevertheless, during that famous “Race” in the summer of 1888, some magnificent engine work was accomplished. Thus, for instance, the North-Western and their partners actually ran from Euston to Edinburgh, 400 miles, in 427 minutes. Then the Great Northern and their partners, the East Coast route, next day covered 393 miles in 423 minutes, this journey including 124½ miles from Newcastle to Edinburgh covered in 123 minutes. This speed is, of course, more than a mile a minute, and kept up for slightly over two hours.

The third-class passenger was at the root of the matter. Companies are finding out they must consult his convenience; and the beginning of the “Race” was probably the announcement that the “Flying Scotchman”—the 10 o’clock morning train from King’s Cross—would carry third-class passengers. Hitherto it had beaten its rival, the West Coast route (run by the North-Western and its partner, the Caledonian), as to speed, but had conveyed only first and second-class passengers.

Thereupon the West Coast announced that they would reach Edinburgh in nine hours. As this route is harder for engines—for it climbs the Cumbrian Hills, and is, moreover, seven miles longer—this would mean faster running and harder work than its rivals. The Great Northern, which according to its well-deserved reputation probably tops the world for speed, could not brook this, so the East Coast route reduced its time from nine hours to eight hours and a-half.

So the contest stood for about a month, when the West Coast calmly announced the same time for its[49] journey. Thenceforward the blows fell thick and fast. It was a battle of giants, but fought with good temper and gentlemanly honour on both sides.

The West Coast were arriving at Edinburgh at half-past six. “The Flying Scotchman,” by the East Coast route, thereupon drew up in the Scotch capital at six o’clock. Then the West Coast ran to Edinburgh in eight hours, stretching away from Euston to Crewe, 158½ miles in 178 minutes, without a stop—probably the longest run without a break ever made. The Caledonian Company, the North-Western’s partner, then ran from Carlisle to Edinburgh, 100¾ miles, in 104 minutes. The North-Western thereupon actually ran from Preston to Carlisle, over the Cumberland Hills, ninety miles in ninety minutes—a magnificent performance hard indeed to beat, if, in fact, it ever has been really beaten; while, later on, the same Company ran from Euston to Crewe in 167 minutes instead of their remarkable 178 minutes a few days previously. This, with the other accelerations, gave the West Coast their record run of 400 miles in 427 minutes of running time, which took place on the 13th of August. But the East Coast had also accelerated, the North-Eastern covering 205 miles in 235 minutes, and the Great Northern rendering an equally good, if not better, performance, the whole 393 miles being covered in 423 minutes. Some of the miles on the East Coast route sped by at the rate of seventy-six an hour.

To accomplish these runs the weight of trains was cut down, and the times of stoppages reduced or abolished altogether. But the expense was too great. It did not really “pay” in convenience or in money, and to these judgments companies must bow. But considering that the Great Northern reaches Grantham, 105¼ miles, in 115 minutes as a daily occurrence, an approximate running of near a mile a minute, and that the North-Western can run at an average of fifty-five miles an hour, the locomotive has amply justified George Stephenson’s prophecy when he made[50] “Blucher,” that there was no limit to the speed of the locomotive, provided the work could be made to stand.

Mr. C. R. Deacon also prophesied a few years since in an American magazine that a hundred miles an hour would be the express speed of the future, provided that passengers would give up luxurious cars and dining and sleeping carriages. At present it seems questionable if they will do so.

But speed is by no means the monopoly of the North. Other companies beside the owners of the East and West Coast routes to Scotland can run expresses equally or almost as fast. There is the “Flying Dutchman,” for instance, of the Great Western. It daily covers the 77¼ miles from London to Swindon in 87 minutes. And the tale is told by Mr. W. M. Acworth, on the authority of an inspector who was in charge of the train, that a famous Great Western engine, the “Lord of the Isles,” which was in the Exhibition of 1851, actually whirled a train from Swindon to London, 77¼ miles in 72 minutes.

Some of those older engines could run bravely. Mr. Acworth reports that “a Bristol and Exeter tank-engine with 9 feet driving wheels, a long extinct species,” pelted down a steep incline at the speed of 80 miles an hour, many years since, and it has never been surpassed. The fastest speed during the Race to Edinburgh days seems to have been 76 miles, but perhaps the weight of the trains may have accounted for this. Mr. Acworth himself is believed to have accomplished the fastest bit of advertised journeying in the world. He went down on the “Dutchman,” and leaving Paddington at 11.46, he caught the return train at Swindon and was back at 2.45, having covered 154½ miles, with five minutes for refreshments, in 177 minutes. The line is easier on the up journey to London, and mile after mile sped by at a rate of over 60 miles an hour. From 56½ to 58 seconds was the chronograph’s record again and again, while on the down journey to Swindon he records a burst of 34½ miles in 34 minutes.

The gradients of the railway form of course a most important factor in the question of speed. The Midland has one of the hardest roads in England for steep slopes, yet its magnificent engines bring its heavy trains from Leicester, 99¾ miles in 122 minutes. Considering the high levels the locomotives have to climb, only to sink again to low flats, as about the Ouse at Bedford, this performance is really as fine as some of the superb running of the Great Northern.

The Southern lines out of London have no long distances to cover as the Northern, unless it may be the South-Western to Plymouth. The South-Western to Bournemouth and Exeter, and the mail trains on the South-Eastern, Chatham and Dover, and the Brighton trains can also show some excellent work as regards speed.

The government of a large railway now has grown to something like the rule of a small state. Sir George Findlay, the general manager of the North-Western[52] Company, in his evidence before the Labour Commission in 1892, deposed that the capital raised for British railways amounted to the vast sum of 897 millions of pounds; that the receipts were 80 millions yearly, that much more than half of this immense amount, namely 43 millions, yearly was paid in wages, and that half-a-million of men directly or indirectly were given employment.

To such enormous dimensions has the railway developed. And the locomotive engine is the centre and soul of it all. Stephenson got it, so to speak, on its right lines of working, and it has run along them ever since, until in its great capacity for speed, its power for drawing heavy loads, and its strength and beauty of construction it may fairly be called one of the wonders of the world.

THE “COMET” APPEARS.

“If only people could reach the place easier, I could do more business.”

So mused Henry Bell of Glasgow about the year 1810. He was an ingenious and enterprising man, and he had established a hotel or bathing-house at Helensburgh on the Clyde. But he wanted more visitors, and he puzzled his brain to discover how he could offer facilities for them to reach the place.

He tried boats, worked by paddles, propelled by hand; but these proved a failure. They had been in use years before, though perhaps he knew it not. Tradition says that boats fitted with paddle wheels and worked by oxen in the boat, were known to the Egyptians, but perhaps tradition is wrong. The Romans and the Chinese also are said to have known wheel boats, the wheels worked by men or by animals—in the case of the Chinese apparently by men alone. A similar kind of boat appears to have been tried on the Thames in the seventeenth century; but whether Bell knew of these things or not, his experiments of[54] the same kind did not answer. What was to be done?

He determined to build a steamboat. At first sight there does not seem to be much connection between baths and steamboats, but apparently it was the ownership of the one which led Henry Bell to build the other, and to become the first man in Great Britain who used a steamboat for what may be called public and commercial purposes.

She was a queer craft. Her funnel was bent and was used also as a mast, and she poured forth quantities of thick smoke. But she was successful, and laboured along at the rate of five miles an hour. Up and down the river she plied, and whatever else she did, or did not, she made the good folk of those days understand that steam could be applied to navigation.

She was called the Comet, not because, even in the opinion of her owner, she resembled a blazing meteor, but because, to use Bell’s own words, “she was built and finished the same year that a comet appeared in the north-west part of Scotland.”

“Whatever made you think of starting a steamship?” we can imagine a friend asking him as they stood on the bank and watched the Comet with her paddles shaped like malt shovels, splashing up the water.

“Partly it was Miller’s experiments, and partly it was a letter from Fulton. You know, Fulton has put the Clermont successfully on American waters. He had been over here talking with Symington, who had a steamer on the Forth and Clyde Canal you remember, and he wrote to me also asking about machinery and requesting me to inquire about Miller’s boats, and send him drawings.”

“And did you?”

“Oh ay, I did; but when he replied afterwards that he had made a steamboat from the drawings though requiring some improvements, I thought how absurd it was to send my opinions to other countries and not put them into practice in our own.”

“So you made the Comet?”

“Well, I made a number of models before I was satisfied; but when I was convinced the idea would work, I made a contract with John Wood & Co., of Port-Glasgow, and they built me this boat, which I fitted up with engine and paddles, as you see. John Robertson actually set up the engine. We will go aboard presently, and you shall see her.”

They did so, and this is something of what they saw. They found a small vessel, forty feet long and ten and a-half wide, and only about twenty-five tons burthen. The furnace was bricked round, and the boiler, instead of being in the centre, was seated on one side of the ship, with the engine beside it. But the funnel was bent and rose aloft in the middle, and it answered the purpose of a mast—to carry sail.

“But look at the machinery,” we can imagine Bell saying to his friend. “We have one single cylinder, you see. The piston is attached to a crank on an axle. This axle carries a big cog wheel, which, working two more placed on the paddle axles, causes them to revolve.”

“And the paddles?”

“Well, you see, we have now two sets on each side, and each paddle is shaped something like a malt shovel; but I think I shall alter them, and have paddle wheels soon.”

Bell carried out his improvement, and in a short time he did adopt the better form of paddle wheel. The improved Comet, with a new engine, attained six or seven miles an hour. But before this, Mr. Hutchison, a brewer, built another boat, bigger than the Comet, and her engine was of ten horse-power, while the Comet’s was but three. She travelled at an average of nine miles an hour, and her fares were but a-third of those charged by coach.

The news of the steamers on the Clyde became noised abroad, and steamboats began to appear on other British rivers. The success of the new venture became assured.

But how had it been brought about? Bell had referred to the labours of others, and, indeed, his was not the first steamboat, though, doubtless, it was the first in Britain to ply for passengers.

The truth is, that as with the locomotive, several minds were working towards the same object. And among those early steamboat seekers Patrick Miller, of Dalswinton, and William Symington, of Wanlockhead Mines, are entitled to high place.

Indeed, Symington is said to have built the “first practically successful steamboat” in the world. She was called the Charlotte Dundas, and, in 1802, she tugged two barges, together of about 140 tons, nineteen and a-half miles, in six hours, with a strong wind against her.

She was built under the patronage of Lord Dundas, and was intended to be used for towing on the Forth and Clyde Canal, but the proprietors of the canal would not adopt this new method of propulsion; they feared that the wash from the wheels would damage the canal banks. So the Charlotte Dundas, successful though she was to a certain extent, had to be beached and broken up. But Fulton and Bell both inspected her, and we may infer that what they saw, influenced their subsequent action.

The engine of the Charlotte Dundas was of the “double action” character, introduced by Watt, and it turned a crank in the paddle wheel shaft. The wheel was placed at the stern; and boats with their wheels thus placed are still made for use in particular places. Thus Messrs. Yarrow built one in 1892, to voyage in the shallow rivers and lagoons on the west coast of Africa; the idea being that a screw-propeller would have been likely to become fouled with weeds.

The Charlotte Dundas, we say, has been regarded as the “first practically successful steamboat ever built.” No doubt it was so, and the credit must be largely given to William Symington. But his success, and that which crowned the labours of others, were rendered possible by the inventions and improvements of James Watt.

Others had experimented before Symington. Thus, if royal records in Spain may be trusted, a certain Blasco de Garay exhibited a steam vessel, in 1543, at Barcelona. He placed a large cauldron of boiling water in the ship, and a wheel on each side. Certain opinions concerning it were favourable, and Blasco was rewarded; but the invention was kept secret, and appears to have died.

Then, in 1655, the Marquis of Worcester is said to have invented something like navigation by steam. Later on, Jonathan Hulls took out a patent for a paddle steam vessel in 1736; and among others, in England, France, and America, the Marquis de Jouffroy made a steamer which was tried at Lyons, in 1783.[58] Then, in 1787, Patrick Miller is said to have patented paddle wheels in Britain.

Miller was a retired gentleman at Dalswinton, in Dumfriesshire, who took much interest in mechanical affairs. He experimented with paddle wheels, and he also endeavoured to improve naval building. At first the wheels appear to have been turned by men, and there came a day when a double boat of Miller’s, worked by a couple of wheels with two men to turn each wheel, sailed with a Custom House boat, and the need of more efficient motive power to revolve the wheels became very marked. Then the idea of steam navigation was born, or re-born.

There was a gentleman named Taylor, living with Miller, as tutor to his sons, and he often took part in the experiments with the boats. It is said that Taylor suggested the use of steam to propel the vessel, and that Miller doubted its practicability. However, he decided, at length, to try it, and in those summer days of 1787 the subject was much talked of at Dalswinton. Taylor mentioned the matter to Symington, who, it seems, was a friend of his, but it is not quite clear whether he had himself thought of this use of steam. However, in October, 1788, the experiment was tried on Dalswinton lake.

A boy was there who afterwards became Lord Brougham, and Robert Burns was also there; and, no doubt, the experiment was watched with much interest.

It appears to have been successful, and next year a bigger boat was tried on the Forth and Clyde Canal, again with some success. But whether Mr. Miller thought he had now spent enough money on these experiments—and Carlyle says Miller “spent his life and his estate on that adventure, and died quasi-bankrupt and broken-hearted”—or whether he was satisfied with the results attained, he abandoned all further effort. Possibly he did not see any opportunity of utilising the invention further. At all events, the development of the steamboat made practically no progress[59] until Symington commenced his experiments under Lord Dundas.