Title: Manual for submarine mining

Author: United States. War Department

Release date: May 26, 2024 [eBook #73701]

Language: English

Original publication: Washington: Government Printing Office

Credits: deaurider and the Online Distributed Proofreading Team at https://www.pgdp.net (This file was produced from images generously made available by The Internet Archive)

EDITION OF 1912

WASHINGTON

GOVERNMENT PRINTING OFFICE

1912

War Department,

Document No. 399.

Office of the Chief of Staff.

This Manual for Submarine Mining, revised to 1912, is approved and published for the confidential information and guidance of the Army of the United States. Under no circumstances shall its contents be divulged to persons not in the military or naval service of the United States.

By order of the Secretary of War:

| Page. | ||

| Chapter I. | Definitions and general principles | 7 |

| II. | Matériel of the system | 11 |

| III. | Loading room duties | 34 |

| IV. | Locating distribution box, laying multiple cable, | |

| marking out mine field | 42 | |

| V. | Assembling and planting mines | 48 |

| VI. | Test of mines and apparatus | 56 |

| VII. | Taking up mines | 62 |

| VIII. | The mine command | 65 |

| APPENDIXES. |

||

| 1. | Explosives | 69 |

| 2. | Oil engine and generator | 77 |

| 3. | Storage battery | 84 |

| 4. | Submarine mine cable | 92 |

| 5. | Care and preservation of matériel | 107 |

| 6. | Instructions for masters of mine planters | 111 |

| 7. | Manual for small boats | 115 |

| 8. | Supply list | 121 |

[Pg 7]

A submarine mine consists of an explosive charge inclosed in a water-tight case, and a firing device, the whole intended to be submerged in a waterway which it is desired to close against the passage of an enemy’s vessels.

With respect to the position of the case containing the explosive, submarine mines are of two classes, buoyant and ground.

In the buoyant mine, the case contains the explosive and the firing device, and has such excess of buoyancy that it would float were it not held below the surface by a mooring rope and an anchor. The submergence is such that, while the mine would be struck by the hull of a passing vessel, it is not so near the surface as to be seen.

Buoyant mines may be planted and operated successfully in water 150 feet deep. They should not, in general, be used where the depth of water is less than 20 feet.

In the ground mine, the case contains the explosive and the firing device, and is heavier than the displaced water; it therefore rests upon the bottom and requires no anchor. Ground mines are not used where the depth of water exceeds 35 feet.

With respect to the means used to fire them, mines may be classed as mechanical and electrical.

Electrical mines are, in turn, of two general classes, controllable—in which the firing device is under control after the mine has been fixed in position; and noncontrollable—in which no such control is had.

Mechanical and noncontrollable electrical mines are intended to be fired only by the blow of a passing vessel. When once in position they [Pg 8] are dangerous alike to friend and foe, while controllable mines may instantly be made safe for friendly vessels or as quickly made dangerous to vessels of the enemy.

Controllable electrical mines are arranged so as to give a signal to the operator when they are struck. They may be set to fire automatically when struck or tampered with, or may be fired at the will of the operator. In the latter case the firing may be delayed, in which case the operator fires the mine some short interval after the signal indicates that it has been struck; or by observation, in which case he fires it after the position-finding system shows that the vessel has come within the mine’s destructive radius.

The considerations involved in the location of mines are of two general classes, tactical and local.

Tactical considerations deal with the position of mines with reference to the other defenses. Local considerations deal with the width and depth of the channel, the swiftness of the current, the variation of the tide, and the relative importance of the harbor.

Where ordinary ship channels are unobstructed it is possible for modern battleships, with their high speed and heavy armor, to run by shore batteries, at least in the night or during a fog; hence the defense of such channels should not be left to guns alone.

On the other hand, where mines are unprotected by the fire of shore batteries it is possible for an enemy to remove or disable them.

Therefore guns and mines, the two elements of the fixed defenses of a harbor, are mutually dependent, and when the location of one has been decided upon that of the other must conform thereto.

Within the zone between 4,000 and 8,000 yards of the main defense the fire of heavy guns is destructive for warships, yet the latter are at such a distance that their rapid-fire guns will be of little effect against the batteries. [Pg 9]

Moreover, at 4,000 yards vessels are just beyond the inner limit of mortar fire.

If possible, therefore, hostile vessels should be held in this zone by some obstacle. Such obstacle is afforded by a mine field.

On the other hand, attacks upon a mine field are most liable to be made by small boats at night. If the mine field be at too great a distance from the defenses, these boats will not be revealed by the mine searchlights. Furthermore, for protection against such attacks, the defense relies upon rapid-fire guns of relatively limited range.

Due to the above considerations the outermost mines are usually placed between 3,000 and 4,500 yards from the main defense.

In general, there should be in each main channel at least three lines of mines.

The elements of a mine system are:

1. The mining casemate, consisting typically of four rooms: (1) The operating room, containing the power panel and the operating boards; (2) the engine room, containing the engine and the generator; (3) the battery room, containing the storage battery; and (4) the sleeping room for the personnel.

2. The multiple cables, 7 and 19 conductor, leading from the casemate out to the distribution boxes, one of which is in the center and rear of each group of mines.

3. The single-conductor cables, radiating to the front from the distribution boxes, one leading to each mine.

4. The mines, in groups of 19 or less, extending across the waterway to be defended, planted approximately 100 feet apart and anchored so as to have a submergence of about 10 feet at low water. The groups are numbered 1, 2, 3, etc., from left to right of the observer stationed in rear of the line, and the mines in each group are numbered similarly, No. 1 being on the left, No. 10 in the center, and No. 19 on the right. [Pg 10]

The groups composing a line of buoyant mines are not usually planted in prolongation of each other, but with a space for the passage of friendly vessels, and also for the movement of the planter when at work upon adjacent groups. Groups of ground mines may be placed in prolongation of each other or between the groups of buoyant mines, as they will always be below the hulls of passing vessels.

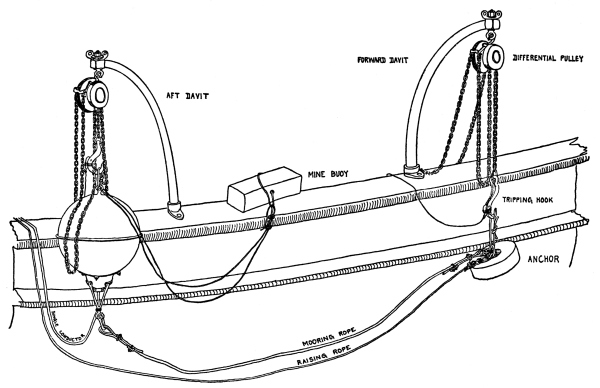

5. The mine planters and other boats with the necessary equipment for planting and maintaining the planted mines.

6. The range-finding system, the same as or similar to that used for the guns, enabling accurate plotting of the positions of the individual mines, and consequently permitting vessel tracking and observation firing.

7. The searchlights, for illuminating the mine fields at night.

8. The rapid-fire guns, for the protection of the mine fields.

[Pg 11]

The generating set.—This consists of a D. C., shunt-wound generator driven by a kerosene oil engine, or of a direct-connected gasoline set. (For method of operation of a Hornsby-Akroyd oil engine, see Appendix 2.)

The storage battery.—This is a 40-cell chloride accumulator, with a normal charge and discharge rate of 5 amperes. The voltage may be taken at 2 volts per cell; the internal resistance is negligible. Directions for setting up, care, and usage of the storage battery are given in Appendix 3. The 5-ampere battery is the standard equipment at the present time, but the new installations will have batteries with a normal charge and discharge rate of 15 amperes.

The motor-generator, D. C.-A. C.—This is a D. C.-A. C. (60-cycle, single phase) machine, running on D. C. voltage (80-110) and designed to give one-half kilowatt at 80 volts. To insure against breakdown two of these motor-generators are supplied to each casemate.

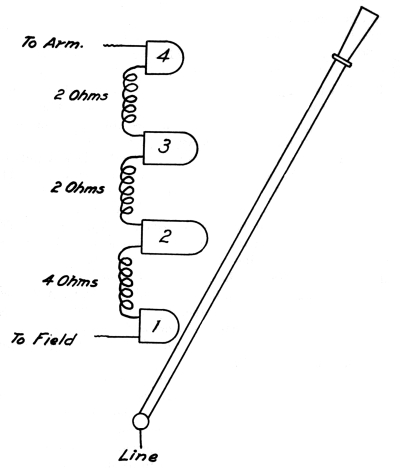

Starting switch.—This is a 4-point lever switch and is used to start the motor-generator and to accelerate it to full speed. To insure against breakdown two of these motor-generators circuit to the fourth point. Resistances are connected between the points, as shown in figure 1. The contact made at point 1 is not broken as the lever is moved to its successive positions. It is seen that the total resistance is 8 ohms; it is all in the armature circuit when the switch blade is in the first point; 4 ohms when in the second point; 2 ohms when in the third point; none when in the fourth point. The operation of closing the lever short circuits in turn the resistances 4, 2, and 2. [Pg 12]

The casemate transformer.—This is a step-up transformer, of the oil-insulated core type, and is rated at 60 cycles, 500 watts, 80 volts primary and 500 volts secondary, when carrying full load.

Fig. 1.—Starting switch.

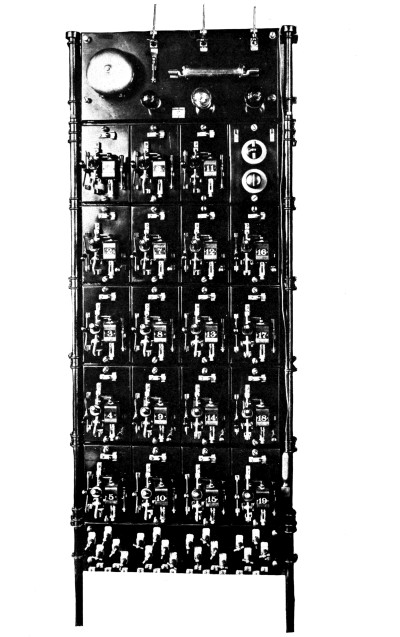

The power panel.—This panel is shown in figure 2, its wiring diagram in figure 18 at the end of the book. It consists of an enameled slate panel upon which the apparatus is mounted. It is 32 inches wide, 69 inches high, and is set up with its face 34 inches from the wall in rear.

Fig. 2.—POWER PANEL.

[Pg 13] Across the top are two lamps, a double circuit breaker, a D. P. D. T. switch, and a single circuit breaker. Below these there are an ammeter, an A. C. voltmeter, and a D. C. voltmeter. Below the ammeter is a battery rheostat and below the D. C. voltmeter a field rheostat. On a bracket at the side there is a mil-ammeter, with a 16 c. p., 110-volt lamp in series with it.

The remaining switches, receptacles, and attachments are sufficiently well indicated in the figures.

Switch No. 1 controls the lamps at the top of the board. When it is up, they are supplied from an external source of power. When it is down, they are supplied from the storage battery.

The D. C. terminals are all carried to one terminal bar, the A. C. terminals to another. All terminals and all switches are labeled.

Provision is made for energizing the D. C. busses:

(a) From an external source of power: Close single circuit breaker and close switch No. 2 to the right—facing the board.

(b) From the casemate generator: Close single circuit breaker and close switch No. 2 to the left—facing the board.

(c) From the storage battery: With switch No. 2 open, close double circuit breaker.

Feeder switches are plainly marked. The D. C. switches supply power as follows:

No. 3. When up, supplies the operating boards (negative pole to boards, positive to earth); when down, it is spare.

No. 4. When up, supplies motor-generator No. 1; when down, motor-generator No. 2.

No. 5. When up, supplies the mine commander’s station.

No. 6. When up, supplies casemate lamps; when down, it does the same, but the power is now drawn from an external source and not from the D. C. busses.

No. 7. When up, grounds the positive bus and connects the negative bus through the protective lamp and mil-ammeter to the mil-ammeter lead.

The A. C. switches supply power as follows:

No. 8. When up, supplies the operating boards, one pole to boards, the [Pg 14] other to earth through an independent lead; when down, it does the same, but the side grounded is grounded through a choke coil.

No. 9. When up, energizes the A. C. busses from motor-generator No. 1; when down, the A. C. busses from motor-generator No. 2.

No. 10 is spare.

No. 11. When up, supplies power to the primary of the testing transformer; when down, it is spare.

No. 12. When up, supplies power from the secondary of the testing transformer to the test fuses.

Voltmeter receptacles and plugs, all of which are properly marked, are provided for obtaining the reading of the A. C. and D. C. voltages. The D. C. receptacles are on the right and the A. C. on the left. The first receptacle of each set is spare to hold the plugs when the latter are not in use.

With the D. C. plug:

In the second receptacle, the voltage of the casemate generator is indicated.

In the third receptacle, voltage of external D. C. power.

In the fourth receptacle, voltage of storage battery.

With the A. C. plug:

In the second receptacle, voltage of A. C. power on the busses is indicated.

In the third receptacle, voltage of external A. C. power, if the latter is supplied.

In general, no external A. C. power should be led into the casemate, as the system would be unsafe, owing to the liability of a “cross.” The standard system is perfectly safe, as it is impossible for a mine to be fired when the motor-generators are idle.

The double circuit breaker is an ordinary single-coil breaker. The single circuit breaker is an overload and reverse-current circuit breaker. The reverse-current coil has two windings, one of which is bridged across the power supply, and the other is in series with it. On charge, the effect of these coils is differential, and on discharge it is cumulative and will trip the circuit breaker when the current from the storage battery exceeds 2 amperes.

Fig. 3.—OPERATING BOARD.

[Pg 15] To charge the storage battery:

(a) From an external source of power: Both the single and the double circuit breakers are closed and switch No. 2 is closed to the right (facing the board).

(b) From the casemate generator: Both circuit breakers are closed and switch No. 2 is closed to the left (facing the board).

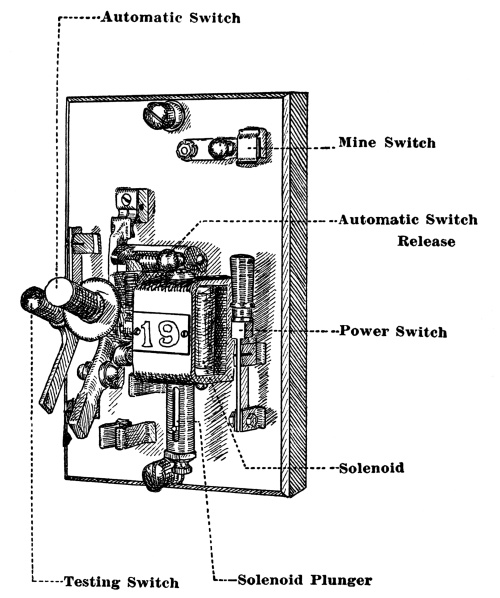

The operating board.—A front view of this is given in figure 3, its wiring diagram in figure 18 at the end of the book. One is required for each group of 19 mines. It consists of an iron frame to which are attached a signal block, a master block, 19 mine blocks (1 for each mine), busses, and a terminal bar with 19 numbered terminals. The frame is 78 inches high by 24 inches wide. It should be set up so that its face is 34 inches from the wall in rear.

The signal block (see fig. 18).—This is an enameled slate block 24 inches wide and 11 inches high, upon which are mounted three binding posts, three lamps (red, white, and green), a bell and bell switch, a 90-ohm non-inductive resistance in parallel with the white lamp, and a 125-ohm resistance in series with the bell. The binding posts are marked “Earth” or “G.,” “A. C.,” and “D. C.,” respectively. The bell, the 90-ohm non-inductive resistance, and the 125-ohm resistance are so indicated on the figure. The lamps are marked as follows: Red, “R. L.”; white, “W. L.”; green, “G. L.”

The circuit, under normal conditions, is: From negative D. C. bus on power panel, to switch 3 closed up, to “operating board” terminal, to D. C. lead, to D. C. post on signal block, through green lamp, to D. C. jaw on master block, to D. C. bus on operating board, through power switch P on mine block, through solenoid S, to middle of testing switch T, to upper contact of same, to upper contact of automatic switch A, to middle of same, to mine switch M, through same to terminal bar, through 19-conductor and single-conductor cables, through mine transformer primary, to mine case, to ground, to D. C. “earth” terminal on power panel, to switch 3, and to positive D. C. bus on power panel. [Pg 16]

Green lamps of 8, 16, and 32 candlepower are supplied. The 16-candlepower green lamp glows dimly when 19 mines are connected to the operating board and all are free from short circuits, grounds, or abnormal resistances. If it should glow abnormally bright, due to grounds, a 32-candlepower lamp should be substituted. If it should glow very dimly, due to a less number of mines connected, an 8-candlepower lamp should be used.

A short circuit in a mine circuit causes the green lamp to glow more brightly.

Breaks in conductors not causing short circuits will not be revealed ordinarily by this lamp. To detect breaks, tests of individual mines must be made.

The red lamp glows and the bell rings when any automatic switch is down. The circuit under this condition is:

From negative D. C. bus on power panel to switch 3 closed up, to “operating board” terminal, to D. C. lead, to D. C. post on signal block, through green lamp to D. C. jaw, to D. C. operating board bus, through power switch on mine block whose automatic switch is down, through insulated pin of lower arm of automatic switch, to lower point of testing switch T, to operating board lamp bus, through bell, 125-ohm resistance and bell switch, and red lamp in parallel, to “earth” post, to earth lead, to D. C. “earth” terminal on power panel, to switch 3, and to positive D. C. bus on power panel.

The resistance of the bell is such that a resistance of 125 ohms must be placed in series with it to make the joint resistance of the red lamp-bell circuit so large that if one automatic switch is down it will not interfere with the tripping of another.

The white lamp, W. L., is in the firing and A. C. testing circuits. The 90-ohm resistance is in parallel with this lamp, and in addition to protecting it from excessive current, serves to keep the firing circuit complete should the lamp burn out.

The master block (see fig. 18).—This is an enameled slate block 6 inches wide by 9½ inches high, upon which are mounted two jaws for the terminals of a jumper, a testing switch, T. S., and a firing switch, F. S.

Fig. 4.—MINE BLOCK.

[Pg 17] The testing switch, T. S., is used to determine if the A. C. power be on the signal block. If so, when it is closed the white lamp on signal block glows. This switch is marked to indicate its “off” and “on” positions. When “on” the circuit is as given in “test of the delivery of the A. C. power to the operating board,” Chapter VI.

The firing switch, F. S., is used to throw the A. C. power on the operating board A. C. busses. This is marked to show its “on” and “off” positions. No mine can be fired unless this switch is in its “on” position. When “on” the firing circuit is as follows:

From A. C. bus on power panel to switch 8 closed up, to “operating board” terminal, to A. C. lead, to A. C. post on signal block, to white lamp and resistance in parallel, to A. C. jaw, through firing switch, F. S., to A. C. bus on operating board, to lower point of automatic switch when it is closed down, to middle point of automatic switch, through mine switch to terminal bar, through 19-conductor and single-conductor cables, through mine transformer primary, to mine case, to ground, to A. C. “earth” terminal on power panel, to switch 8, and to other A. C. bus on power panel. The white lamp glows after the mine has been fired.

The mine block (see figs. 4 and 18).—This consists of an enameled slate block, 6 inches wide and 9½ inches high, on which are mounted four switches.

1. The upper switch is the “mine switch.” When it is open the corresponding mine is cut out and can not be fired. It is placed horizontally on the blocks of the old model and vertically on those of the new model.

2. The right-hand switch, a S. P. S. T. knife switch, is the “power switch.” When it is closed the D. C. power is on the block and the automatic switch will function when the corresponding mine is struck. When it is open the mine can be fired by raising the automatic switch release, thus tripping the automatic switch.

3. The central switch is the “automatic switch,” a single-pole double-throw switch, operated by the plunger of a solenoid. Through its [Pg 18] lower arm there passes an insulated pin which, when the switch is down, makes connection between two contacts to the right and left of this arm.

If for any cause the current through the solenoid rises above that for which it is set (normally 0.075 ampere), its plunger is drawn up and the switch is tripped. Such rise in current is produced when a mine is struck, the resistance through the circuit-closer circuit being far less than that through the primary coil of the transformer. Such would also be the case when a mine cable is grounded.

When the automatic switch is tripped, the D. C. circuit to the mine is broken at its upper contact (see fig. 18) and D. C. circuit through red lamp and bell is made through the insulated through pin in the lower arm, thus giving warning. If at the same time A. C. power be on the busses and the firing switch on the master block be closed, A. C. will be thrown on the mine through the lower contact of the automatic switch, and the mine will be fired.

Just above the plunger of the solenoid there is a red knob attached to the tripping bar of the automatic switch release. This enables the automatic switch to be released by hand in observation firing and in testing.

4. The left-hand switch, a S. P. D. T. switch, is the “testing switch.” It is used to test the automatic switch, which should open when the testing switch is thrown down. The bell switch should be opened before throwing down testing switch. When the testing switch is in this position, the circuit being broken at its upper contact, the mine is cut out, and in place of the mine there is thrown in the red lamp of the signal block. The resistance of this red lamp is greater than that of the mine circuit when the mine is struck, so that if the automatic switch works for the current through the red lamp it will certainly work for that through the circuit closer when the mine is struck.

The circuit when the testing switch, T, is down and before the automatic switch drops is: From negative D. C. bus on power panel, to switch 3 closed up, to “operating board” terminal, to D. C. lead, to D. C. post on signal block, through green lamp, to D. C. jaw, to D. C. bus on operating board, through power switch, through solenoid to middle of [Pg 19] testing switch T, to lower point of same, to operating board lamp bus L, through red lamp to “earth” post, to earth lead, to D. C. “earth” terminal on power panel, to switch 3, and to positive D. C. bus on power panel. The circuit, when testing switch, T, is down, and after the automatic switch has dropped, is the same as the above up to the power switch, then from the power switch through the insulated pin in the lower part of the automatic switch, to the lower jaw of the testing switch, and then the same as the circuit above.

A diagram similar to the wiring diagram, figure 18, at the end of the book should be made of the power panel and of one of the operating boards of each casemate and posted in a conspicuous place in the casemate. Any changes made in the wiring of either of these boards should be made immediately on this diagram.

Submarine mine cable, 19-conductor.—This is an armored cable about 1 inch in diameter and contains 19 insulated single conductors of No. 16 American wire gauge wire (51 mils in dia.). The conductors are arranged in two concentric layers around a single central conductor, the inner layer containing 6, the outer 12. One conductor in each layer is distinguished from the rest by some characteristic mark, as a spiral white thread, a wrapping of tape, or other easily detected mark. The marked conductor in the outer layer is No. 1, that in the inner layer No. 13, and the central conductor is No. 19. The other conductors are numbered at the shore end of the cable in a clockwise direction; at the distant end in a contraclockwise direction.

Submarine mine cable, 7-conductor.—In many cases the 7-conductor cable now on hand can be used to advantage for mine work, particularly in planting groups which do not require great lengths of multiple cable. In all such cases the old grand junction boxes are to be used as distribution boxes, thus providing for separate groups of 7 mines.

Submarine mine cable, single conductor.—This is an armored cable, about three-fourths inch in diameter, and contains an insulated conductor made of 7 strands of soft annealed No. 22 American wire gauge copper wire (25.35 mils in dia.). [Pg 20]

The buoyant mine case.—The service 32-inch pattern is made of 10-pound, ¼-inch, open-hearth steel, of great toughness and elasticity, and is thoroughly galvanized. The shell consists of two hemispheres, ribbed and welded together at the equator, thus avoiding all rivets. Every case before it is accepted is tested with an internal hydraulic pressure of 100 pounds per square inch.

The top hemisphere is provided with an external maneuvering ring; the bottom hemisphere has a hole 5½ inches in diameter at the pole. The edge of the hole is reenforced by a welded ring 1½ inches thick; and near it are four bosses, also welded, carrying screw bolts which project 2½ inches outside to secure the cap.

The cap consists of a hemisphere of 15-pound, ⅜-inch wrought iron, flanged and dished at the base to fit the case, to which it is attached by the four bolts already mentioned. They pass through slots in the flange, which is then held in place by shoes and nuts which are keyed on. The water has free access to the chamber inside the cap. The uses of the cap are: To clamp the Turk’s-head of the mine cable, to cover and protect the portion of the core exposed outside the case, and to serve as an attachment for the wire mooring rope.

A hole 1½ inches in diameter at the pole of the cap is connected by means of a slot with a 3-inch hole punched through the cap between two of the bails. This arrangement permits the entrance or removal of the Turk’s-head without removing the cap from the mine case. The mooring attachment consists of a ring of 1½-inch wrought iron, having a hole 2½ inches in diameter, attached to the cap by three bails of 1-inch wrought iron permanently double riveted to the sides. The cap is thoroughly galvanized.

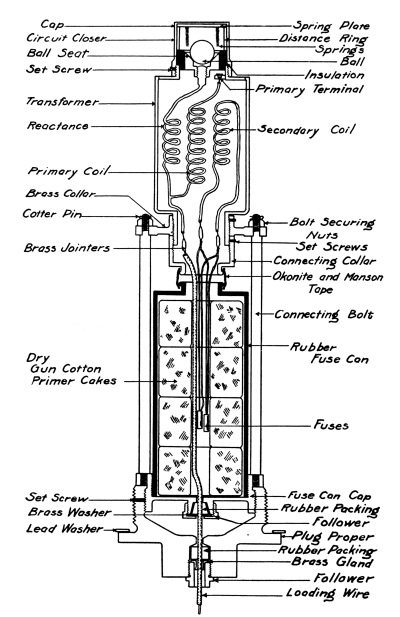

Fig. 5.—COMPOUND PLUG,

OLD MODEL FUSE CAN.

Fig. 6.—COMPOUND PLUG,

RUBBER FUSE CAN.

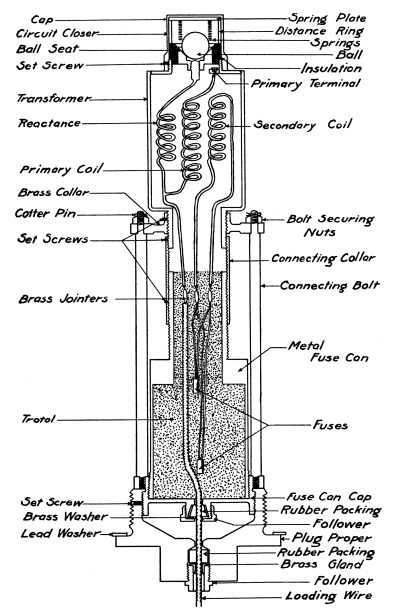

Fig. 7.—COMPOUND PLUG,

TROTOL FUSE CAN.

[Pg 21] The large hole in the mine case covered by the cap is closed by a plug. The joint is made water-tight by a lead washer jammed between the plug proper and the case and by a coating of red lead or similar waterproofing material upon the screw threads. In the strong currents and deep water of some harbors more buoyancy than is possessed by the 32-inch case is required. This is obtained by inserting between the hemispheres a cylinder of 20-pound wrought iron which is stiffened by extra welded ribs for the larger sizes. Such cases are designated by the diameter in inches of a sphere having the same buoyancy. Thus, a No. 40 case is made by inserting a cylinder 32 inches in diameter and 20.4 inches in length between the two hemispheres of a No. 32 case; this is sufficient to make the displacement equal to that of a spherical case 40 inches in diameter. In the latest types the cylinders are made of corrugated mild steel of less thickness, which diminishes very materially the weights of the cases.

The following table exhibits the dimensions and weights of buoyant mines, with trotol fuse cans, complete except the charges and moorings. The actual free buoyancy when planted will be the difference between the displacement and weight as given in the table, reduced by the weight of the charge and of the moorings and cables:

| PLAIN CASES. | |||||

|---|---|---|---|---|---|

| No. | Displacement. | Computed weight, empty. |

Measured weight, empty. |

Length of cylinder. |

Remarks. |

| Pounds | Pounds | Pounds | Feet | ||

| 32 | 635 | 308 | 311 | 0.00 | All are about 33½ inches in |

| outside diameter; the extreme | |||||

| length in each case is 4.3 feet | |||||

| plus the length | |||||

| 33 | 695 | 364 | .17 | ||

| 34 | 762 | 395 | .35 | ||

| 35 | 829 | 427 | .54 | ||

| 36 | 904 | 462 | .75 | ||

| 37 | 982 | 498 | .96 | ||

| 38 | 1,064 | 538 | 1.20 | ||

| 39 | 1,149 | 578 | 1.43 | ||

| 40 | 1,242 | 621 | 625 | 1.70 | |

| 41 | 1,341 | 665 | 1.96 | ||

| 42 | 1,436 | 712 | 2.24 | ||

| 43 | 1,540 | 788 | 759 | 2.53 | |

| 44 | 1,652 | 842 | 2.77 | One extra welded rib. | |

| 45 | 1,767 | 876 | 3.17 | Do. | |

| 46 | 1,887 | 952 | 3.50 | Lot of 1879; | |

| one extra welded rib. | |||||

| 899 | |||||

| 936 | Lot of 1884; | ||||

| one extra welded rib. | |||||

| 47 | 2,013 | 1,011 | 3.85 | One extra welded rib. | |

| 48 | 2,144 | 1,073 | 1,037 | 4.20 | Do. |

| CORRUGATED CASES. |

|||||

| 47 | 1,536 | 572 | 2.24 | ||

| 50 | 2,323.2 | 777 | 4.22 | ||

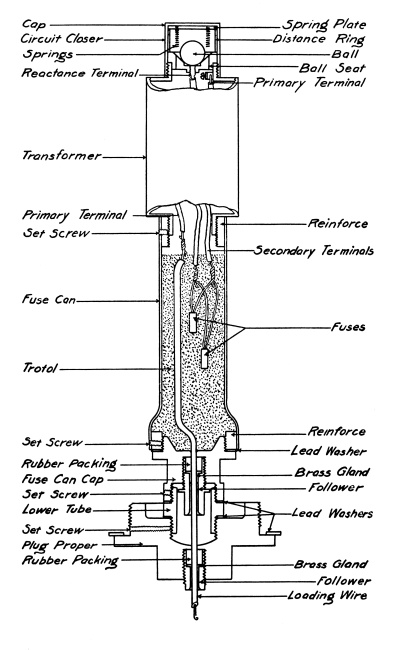

The compound plug, with old model brass fuse can.—A section of [Pg 22] this plug, with the names of all the parts, is shown in figure 5. The brass fuse can is not used when guncotton is used as a priming charge.

The compound plug, with rubber fuse can.—A section of this plug, with the names of all the parts, is shown in figure 6.

The compound plug, with trotol fuse can.—A section of this plug, with the names of all the parts, is shown in figure 7.

In each plug the main parts are screwed together and held in place by set-screws. The connection of the compound plug with the mine case makes an earth plate, of which the electrical resistance in salt water is about 1 ohm.

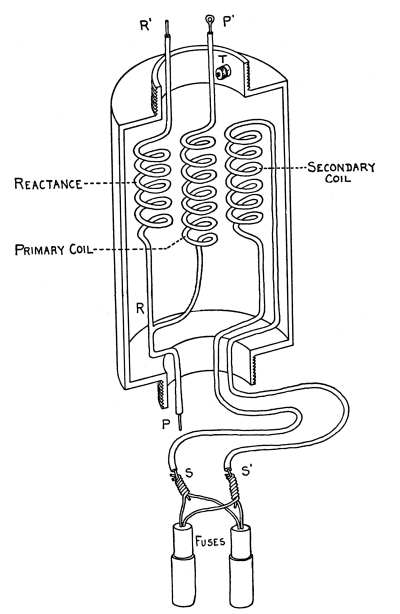

The mine transformer (see fig. 8).—This consists of a cylindrical brass case, which contains the primary and secondary coils of the transformer and the reactance coil. The transformer is screwed into the brass collar or the reenforce and in turn has the circuit closer screwed upon its top. The fuses are attached to the secondary and are fired when proper voltage is applied to the primary. The primary leads are black; those of the secondary are red. The terminal, P′, of the primary coil is left free for the purpose of testing, but when preparing the transformer for use it is attached securely to the binding post, T. The upper terminal, R′, of the reactance is prepared for attachment to the ball seat of the circuit closer.

The normal circuit is from P, through the primary coil (the resistance of which is about 2,400 ohms), to the transformer case, and thence to earth. However, when the mine is struck, so as to close the circuit closer, a parallel circuit is closed through the reactance (the resistance of which is about 130 ohms), thence to the ball seat of the circuit closer, through the ball and springs to the transformer case, and thence to earth. In this latter case, therefore, the resistance is lessened by about 2,300 ohms.

The reactance coil will permit only a small amount of alternating current to pass through it when the ball is displaced, hence mines may be fired whether the ball is displaced or not.

Fig. 8.—MINE TRANSFORMER.

[Pg 23] Two fuses are connected in multiple across the ends of the secondary terminals. These terminals are 10 inches in length, to allow ample margin for inserting fuses in the primer.

The transformer is of the step-down type and is rated at 22.5 watts, 60 cycles, 500 volts primary, and 14 volts secondary.

The mine circuit when normal is such that 80 volts should give only 30 mil-amperes, but a mine may be fired even when the circuit is so defective that 80 volts give 120 mil-amperes.

Furthermore, 150 volts D. C. may be applied to the primary without danger of explosion.

An explosion can not be produced unless the A. C. busses on the operating board are energized, and as long as the firing switch on the master block is open, there is no danger from accidental closing of switches in making mine tests or from short circuits in the mine.

Note.—In designing this transformer the following variations were considered: (a) Omitting reactance and tapping to ball seat beyond primary of transformer; (b) using a condenser; (c) using two sets of fuses, so as to be able to fire with either D. C. or A. C. All were eliminated, as they impaired either the safety, the simplicity, or the efficiency of the system.

The circuit closer.—This, when used with the buoyant mine, consists of the following parts: The cap, the spring plate, the distance ring, the steel ball, and the ball seat, which, when assembled, are mounted on the top of the mine transformer.

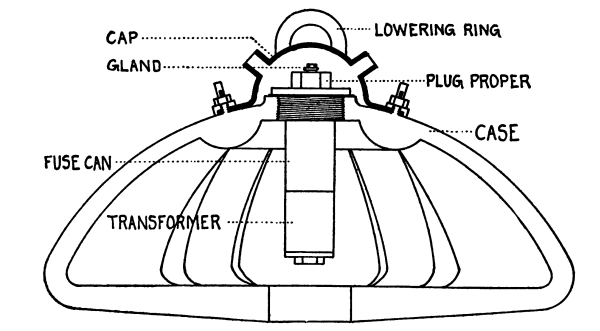

The ground mine case.—The form and details of construction adopted for the service pattern are the following (see fig. 9): The case is cast-iron, in form a segment of a sphere, of which the height is two-thirds of the radius. The bottom is nearly flat, with a central sand-hole plug to empty the casting. Six internal radial ribs are added to give additional supports to the top; the loading hole, 5½ inches in diameter (3 inches in old pattern), is at the pole and is closed by a compound plug. Before acceptance a hydraulic pressure of 100 pounds per square inch must be borne without developing leakage. [Pg 24]

Only one size of ground mine has been introduced into our service. This pattern is designed to contain from 200 to 300 pounds of explosive and to rest on the bottom in water not exceeding 35 feet in depth at high tide. The dimensions are as follows: Radius of the sphere, 21⁹/₁₀ inches; diameter of the base, 40 inches; extreme height, 25 inches; thickness of iron, seven-tenths of an inch; weight, empty in the air, 1,355 pounds; when submerged it loses 515 pounds. The capacity of this case is about 5 cubic feet.

Fig. 9.—Ground mine case.

A mine cap is provided to clamp the Turk’s-head of the mine cable, to cover and protect the portion of the core exposed outside the case, and to serve as an attachment for the mooring and the raising ropes. This cap is held to the mine case by six bolts, and is fitted with two rings, one for attachment of the mooring rope of the circuit-closer buoy and the other for attachment of the raising rope.

The compound plug, ground mine.—This is similar to the compound plug for buoyant mines. The circuit closer is placed in a buoy above the mine.

FIG. 10a.—AUTOMATIC ANCHOR.

[Pg 25] The mushroom anchor.—The 1,000-pound anchor is in shape a right cylinder about 10 inches in height and 26 inches in diameter, slightly dished on the bottom to increase the holding power in mud. For a rock bottom six projecting toes increase the holding power; corresponding depressions on the top permit piling when in store. The heavy anchors, 2,000 and 3,000 pounds, are of the same form. The cylindrical form is adopted to facilitate handling, since in that shape the anchor may be rolled readily on its edge.

The absolute stress of the mine and its moorings upon a mushroom anchor of this kind is easily computed, being the square root of the sum of the squares of the buoyant effort and of the horizontal pressure exerted by the current. The latter, in pounds per square foot of exposed cross section, may be estimated at one-half the square of the velocity of the current in feet per second. A coefficient of safety should cover the jerking effect of the waves and the shocks of friendly vessels. It will, of course, vary with the locality and with the absolute weight of the anchor, but in general a value from 3 to 5 is considered sufficient.

The holding power of such an anchor varies greatly with the nature of the bottom. If this be hard, the dead weight alone must be depended upon; if soft, at least double power may be anticipated. In swift water the buoyant mine can be better held in position by two anchors chained together.

The shackles.—The wire mooring rope is attached to the anchor and to the case by shackles, of which there are two sizes. The anchor shackle consists of a wrought iron strap with two eyes bent into the usual curved form and offering a thickness of 1½ inches at the bottom, where the wear and sand cutting is greatest, and of a 1½-inch wrought iron bolt fitted flush with the outside of the straps. The bolt is held in position by a split key, which, after insertion through a small hole in the bolt and one of the eyes (in the old model), is opened so that it can not work loose.

The mine shackle is lighter, being 1 inch thick at the bottom, with a 1-inch bolt; otherwise it is identical in pattern with the anchor shackle.

Sister hooks.—They are used to connect the bail of the mushroom anchor to the anchor shackle. They are of drop-forged steel of high tensile strength and weigh about 7 pounds per pair. [Pg 26]

The automatic anchor, Artillery type, 1910 (see figs. 10 a and b).—This is a device intended for use with buoyant mines, and by means of which such mines may be anchored in any depth of water, with any desired depth of submergence given automatically.

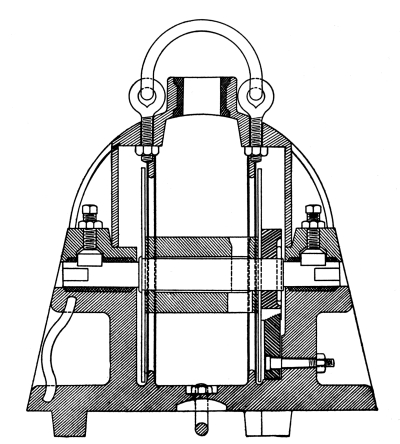

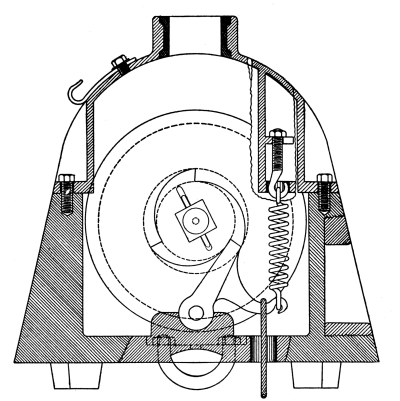

The anchor is bell-shaped, 28 inches in diameter at the bottom, 28½ inches high over all, and composed of the following parts: Body, cover, reel, journal-box caps, ratchet, pawl, pawl spring, distance rope, distance weight, brakes, bails, necessary bolts, wrenches, and crank handles.

The pawl is drawn away from the ratchet by a weight suspended a certain distance below the anchor. This is called the distance weight, and the submergence is regulated by the distance this weight is from the anchor. In falling through the water the mooring rope will unreel and the mine will remain on the surface, but when the distance weight reaches the bottom the pawl spring forces the pawl into the teeth of the ratchet, and as the latter is attached to the reel shaft, it prevents the reel from turning and hence unreeling.

These anchors weigh approximately 1,500 pounds, including the 200-pound distance weight.

In order to control the speed of revolution of the reel, the friction brakes must be adjusted properly. To do this, a pull is put on the mooring rope with a spring balance rigged to show the amount of pull; the pull for a particular size of case is determined by experiment. For a No. 40 mine case the adjusting screws of the brake shoes are regulated so that the reel will revolve slowly when a pull of 300 pounds is registered.

The pawl spring is 9½ inches long and of such strength that a pull of 36 pounds will extend the spring 1½ inches. The pawl spring bolt is of such length that the pawl spring will be just at the point of tension when the top of the pawl spring bolt is flush with the top of the pawl spring-bolt nut and the pawl fully seated in the ratchet.

When the tidal currents are such as to require a heavier anchor to hold the mine than the 1,500-pound automatic anchor, the following combination anchor will be used: Attach a mushroom anchor by means of a mooring rope (about 8 feet long) and clips to the bail in the bottom of the automatic anchor. If necessary, two mushroom anchors may be fastened together by bolts and these attached to the automatic anchor as stated above.

FIG. 10b.—AUTOMATIC ANCHOR.

[Pg 27] A 3,000-pound automatic anchor, similar to the 1,500-pound automatic anchor, is supplied for some localities.

The mooring sockets.—To connect the wire mooring rope to the shackles at the mine and the anchor, a closed socket is attached at each end. The eye of the socket has a clear opening, 1³/₁₀ inches, designed to receive the bolt of the shackle. The end of the rope is passed into the socket, spread out, and secured by pouring in a melted socket alloy.

A substitute method for connecting the wire mooring rope to the shackles is to bend the ends of the mooring rope by means of a small vise around a galvanized iron thimble and fasten the end by two bolted clips.

Wire mooring rope.—This is the highest grade of ¾-inch galvanized-steel wire rope, consisting of 6 compound strands, each made of 19 wires, the whole laid around a steel center. Its breaking strength when new is about 18 tons. Its weight per running foot, submerged, is about eight-tenths of a pound. It is used for mooring mines to mushroom anchors.

Marline-covered wire mooring rope.—For mooring mines to the automatic anchors and for raising rope marline-covered wire rope is used. This rope consists of five outer strands wound around a central hemp core. Each of the outer strands consists of a small twisted wire rope wound around with four strands of marline. One end of the rope is prepared for attachment to the mine by passing it over a thimble and fastening it to the standing part by means of two clips. A shackle joins the thimble and the bail of the mine. The other end of the rope is made secure to the reel of the anchor. The breaking strength of ½-inch marline-covered rope is 17,000 pounds, that of ⅝-inch marline-covered rope is 27,000 pounds. The weight per running foot of the ½-inch rope is 0.5 pound, that of the ⅝-inch rope is 0.8 pound. The weight of this rope submerged is about 60 per cent of its weight in air. [Pg 28]

About 155 feet of the ½-inch and 85 feet of the ⅝-inch marline-covered rope can conveniently be wound on the 6-inch reel of the 1,500-pound automatic anchor.

Marline-covered wire distance weight rope.—For attaching distance weights to the automatic anchor ¼-inch marline-covered wire rope is used. This rope is identical in pattern with the marline-covered wire mooring rope.

The distribution box, 19-conductor.—This is a circular, cast-iron, disk-shaped box which receives the end of the multiple cable, in which taped joints are made between the separate conductors of this cable and the single-conductor mine cables, and from which these mine cables radiate. It is about 27 inches in diameter and weighs about 300 pounds. It consists of two parts, a bowl-shaped bottom 6 inches deep inside and a slightly curved lid. The latter has an iron ring in its center by which the box is raised and lowered.

Eight pins, fastened to the bottom, fit in corresponding holes in the edges of the lid and are slotted for keys by which the two parts are fastened together.

The vertical edge of the bottom is cut with 20 slots, each about 2½ inches deep. One of these is larger than the others and receives the multiple cable; the others are for the single conductor cables. When in use these slots are numbered clockwise from the multiple-conductor slot, looking down into the box. The lid has corresponding projections or lugs which enter these slots, and which, in position, fit snugly against the cable ends. The cables are held from being pulled out by Turk’s-heads worked upon them.

To prevent the cable ends from accidentally slipping out of the slots while joints are being made between them before the lid is put on, the multiple cable is secured by a bolted collar on the inside of the box, the single-conductor cables by clipping their Turk’s-heads under claw-like radial projections cast upon the inside rim between the slots.

The distribution box, 7-conductor.—This box is used with multiple cable, 7-conductor. It consists of two circular plates of cast-iron 21 inches in diameter and three-fourths of an inch thick united by four 1-inch bolts, which are placed in rounded projections [Pg 29] forming the angles of a square. The cables are separately clamped, the top plate overlapping the clamp straps. The multiple cable enters on one side; three single-conductor cables enter on the opposite side, and two on each of the intermediate sides. The top plate is provided with a lowering ring.

The junction boxes.—These boxes, in different sizes, are used in splicing multiple and single-conductor cables; they consist of two rectangular plates of iron or steel united by four ½-inch bolts at the corners. The plates are hollowed in the middle to form a chamber to receive the Turk’s-heads and the joints connecting the conductors. The ends of the plates are curved to admit the cable ends. The Turk’s-heads are clamped to the lower plate by straps and screw bolts, the cavity of the upper plate covering them when bolted in position. Each cable end is thus made fast before the box is closed.

The distribution box buoy.—This buoy is used to mark the position of the distribution box during the planting of mines and subsequently, in practice and in service, until such time as the mine commander desires to remove it. It may be either a can or a keg buoy—a beer keg of one-half barrel capacity is well suited for this purpose.

The mine buoy.—This buoy is used to mark the position of the mine when planted. It may be a small can buoy, preferably cork filled, or a piece of wood with a hole bored through it. The size of the buoy is determined by the swiftness of the current. It is attached to the maneuvering ring of the buoyant mine by 60 feet of ½-inch rope.

The measuring reel and frame.—The frame consists of two longitudinal pieces, 3 by 4 by 66 inches, placed 17 inches apart, center to center. At 11½ inches from each end two cross pieces, 3 by 4 by 20 inches in length, are fastened to the longitudinal pieces with through bolts. At the center point of these cross pieces are placed standards, 3 by 4 by 16¾ inches, which have journals for the axle of the reel, counter-sunk in their upper ends. Two iron braces, one on each side, hold each standard firmly in a vertical position. An iron clamp is also attached to the upper ends of the standards, by means of [Pg 30] which the axle is prevented from jumping out of the journals. Distance from center to center of standards is 43 inches.

The iron axle of the reel is 1½-inch round iron, 54 inches in length. At each end of the axle a screw thread is cut for the nut which holds the crank in place. Inside the screw thread the axle is squared to receive the socket of the crank. Two collars prevent the wooden reel from binding on either standard. The cranks are of the usual design. The drum of the reel is 8½ inches in diameter; heads are 2½ inches thick, made in two layers, cross-grained, and are 24 inches in diameter; length of drum over all is 36 inches. Iron plates are fastened in the center of each head, through which the axle passes. The reel is prevented from turning on the axle by keys.

Three ¾-inch rods pass through the iron plates and drum and bind these parts firmly together.

At 6 inches from the ends of the longitudinal pieces a hole is bored to receive a lag screw, ½ inch by 6 inches, by means of which the whole apparatus can be firmly fastened to the deck.

The brake is a piece of 3 by 3 by 36 inch hardwood, used as a lever to bring pressure on the drumhead. There is one for each side, and, when not in use, each rests on one of the longitudinals, being held in place at one end by two staples and at the other end by a bolt and pin.

Near the drum on one head is a hole through which the inner end of the measuring line can be passed and stapled to the outside of the head.

The cable-reel frame.—The frame is made in two parts which, when in use, are held in proper relative positions by means of two iron ties provided with turnbuckles at their centers. The ends of these ties are bent over at right angles and fit in sockets in the two end parts.

Each end part consists of a standard having an iron head through which works a screw turned by a small lever, the upper end carrying a journal in which the end of the reel axle rests. The lower end of the standard rests on a horizontal piece and has a diagonal brace on each side, the outer ends of these braces being dovetailed into the longitudinal piece and the inner ends into the standard near the top. Dovetailed into the longitudinal piece at its middle point is a piece extending out at right angles, bottom flush with bottom of the longitudinal. A diagonal brace similarly fastened prevents any outward movement of the standard. The whole is held firmly together by bolts and lag screws.

FIG. 11.—BOAT TELEPHONE, MODEL 1906.

[Pg 31] Lag screws are also provided, by means of which the ends of the frames can be fastened to the deck of the vessel if desired.

The reel axle is 2½ by 2½ inch squared iron, rounded at the ends for 6 inches to fit the journals of the frame. A disk secured by a set-screw at one end of the axle and the friction brake wheel at the other end hold the axle in position with respect to the reel.

The brake wheel is 18 inches in diameter. The friction band is 1½ inches by ⅛ inch, and is fastened at one end to one of the standards of the frame. The other end is attached to a lever whose fulcrum is also attached to the same standard.

Boat telephones.—The different models in use are as follows:

(a) Model 1904.—The system consists of two telephone hand sets, a buzzer, and a battery of dry cells of about 8 volts, all connected in series by means of cable and earth connections.

In operating the telephones a call is made by pressing the button, and when talking the lever is held down.

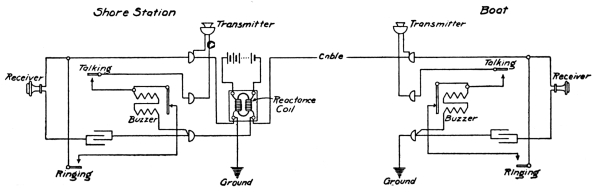

(b) Model 1906.—The system consists of two telephone hand sets, a reactance coil, and a source of energy that will furnish about 15 volts, dry cells preferred, connected as shown in figure 11. The terminals do not have to be poled, as the receiver is not in the primary circuit and can not be demagnetized.

To regulate the buzzer, remove the cap in the base and with a small screw driver loosen the lock nut on the center screw (a small portion of a turn is all that is necessary). With a smaller screw driver the screw may be adjusted to increase or decrease the rate of vibration, increasing or decreasing the sound. Then tighten the lock nut. In case the contact is dirty the entire buzzer and condenser may be removed by [Pg 32] disconnecting the cord and removing the screw on the back of the telephone just below the call button. As the contacts are aluminum, this will seldom have to be done.

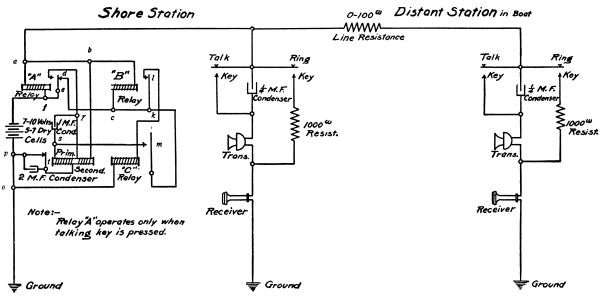

(c) Model 1909.—The system consists of two telephone hand sets, an apparatus box, and a battery of from 7 to 10 volts, all connected as shown in figure 12. The talking and ringing circuits are normally open at the talking and ringing buttons, respectively.

Apparatus box.—Seven dry cells in series should be connected to the posts of the apparatus box marked “+” and “-,” and the post marked “G” connected to a ground plate.

Shore hand set.—The blue cord of the shore hand set should be connected to the ground plate. Either of the red cords of the shore hand set should be connected to the post in the apparatus box marked “L” and the other to the conductor in the cable that is to be used for telephoning purposes.

Boat hand set.—The blue cord of the boat hand set should be connected to the ground plate and one of the red cords to the conductor in the cable to which the hand set on the shore is connected. The other red cord is free.

Signaling.—From figure 12 it will be seen that in either hand set, when neither the ringing nor the talking switch is closed, a condenser within the hand set is in series with the transmitter and the receiver, so that the practical effect is to permit an alternating or variable current to pass through the transmitter and the receiver, but to prevent a direct or continuous current from so doing.

By pressing the ringing key of either hand set the circuit in that hand set is closed through the 1,000 ohms resistance and the receiver to ground. Thus, when the ringing key of the boat hand set is pressed, this allows the direct current from the battery to pass (see fig. 12) through f, e, d, c, “B,” b, a, line, the ringing key, 1,000-ohm resistance, and receiver of the boat hand set, to ground, and back through o and p to battery. Similarly, a circuit through the battery, f, “A,” and a, is made, thus placing relays “A” and “B” in parallel. The relay “B” operates, but relay “A,” being less sensitive than “B,” does not operate. Relay “B” closes the circuit at l, and thus completes the circuit from battery through f, e, d, c, k, l, “C,” o, p, back to battery. This causes relay “C” to operate and to complete a local circuit from battery through f, e, d, k, m, s, primary, t, vibrator, p, back to battery, causing the vibrator to vibrate and inducing in the secondary winding of the induction coil an alternating current, which passes through the 1 M. F. and 2 M. F. condensers, through the hand sets in parallel, and by alternately increasing and decreasing the attraction of the receiver magnets for their diaphragms produces a loud humming sound in each receiver.

Similarly the shore station may call the boat station.

FIG. 12.—BOAT TELEPHONE, MODEL 1909.

[Pg 33] Talking.—When the ringing key is released and the talking key is depressed the 1,000-ohm resistance is cut out and the condenser in the hand set is short circuited. The current is then sufficient to operate relay “A,” and this relay in operating allows the other relays to resume their normal positions.

When the variations in the pressure upon the transmitter diaphragm in either hand set varies the resistance of the corresponding branch circuit a slight variation in the current from the battery is produced. The internal resistance of the battery is sufficient to produce a slight variation in its terminal voltage. The resulting variations in the line voltage, and hence in the drop across the receivers, produce the usual vibrations in the receiver diaphragms. These variations also produce slight variations in the current through the primary winding of the induction coil, resulting in greater variations across the terminals of the secondary winding. Since the secondary winding is in series with the battery, the practical effect is to amplify the variations in the line voltage, and hence in the talking currents.

Successful working of the relays is obtained only by a careful adjustment of the screws which regulate the throw of the armatures. The relay “A” is located in front of the “+” battery post, the relay “C” in front of the “G” post.

In addition to the above matériel there are necessary for the mine system certain electrical instruments, as well as tools, appliances, and supplies requiring no special description, which are enumerated in the supply list. (Appendix 8.)

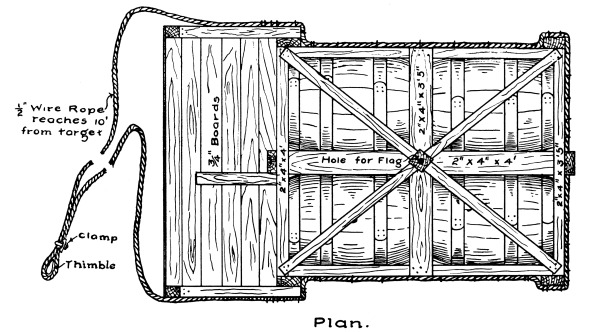

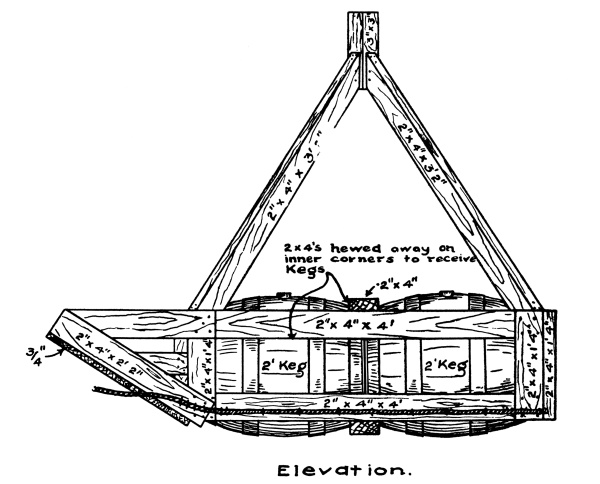

Figures 17a and 17b, at the end of the book, show the construction of an improvised mine target.

[Pg 34]

Making a telegraph joint.—The insulation is removed from the ends for 1½ inches and the wires brightened. The ends to be joined are placed across each other about one-third distance from the insulation, making an angle of about 45° with each other. The wires are grasped firmly at the junction and each free end wound tightly around the other wire for four turns; the winding should be in opposite directions. The ends of the wires are trimmed down so they will be smooth and present no sharp points.

When wires are joined with brass jointers three-fourths inch of each wire is bared and the wires are inserted in the jointer; each end is crimped with pliers in the direction of the longer axis; the rest of the jointer is crimped and the ends or sharp points rounded off. When brass jointers are used care should be exercised not to crimp them too hard, as the wires may be partly cut through and finally broken. Special care must be used with the fuse leads, as the secondary circuit of the mine transformer can not be tested after the compound plug is assembled.

Insulating a joint.—A piece of rubber tape about 2 inches long is used, with ends cut diagonally. The tape is stretched, and starting at a point about three-fourths inch back on the insulation, with the long edge of the tape on the inside, it is wound around the joint under tension, each turn covering the previous turn about one-third. The wrapping is continued until the same amount of insulation is covered on each side, when the wrapping is worked backward over the joint and the end is secured by pressing it firmly a short time or placing a drop of cement under it. [Pg 35]

Making a water-tight joint.—The two ends of wire are scraped clean for about three-fourths of an inch and joined by a brass jointer, which is then crimped. The insulation is scraped clean about 2 inches on each side of the jointer and covered with rubber cement. (Cement is not absolutely essential.) Two strips of rubber tape are cut about 6 inches long, with diagonal ends, and stretched. Beginning about 1½ inches along the insulation, the tape, with the long edge on the inside, is wrapped firmly and tightly until about one-fourth of an inch of the insulation on the other side is covered; it is wound back and forth over the joint so as to taper toward the ends. The other piece of tape is used, beginning at the other end and wrapping as before. The finished insulation should be thick at the middle and taper toward the ends. It should be firm and tight. The insulation is covered with tin foil, wrapped with protective tape, and vulcanized for about 30 seconds. The protective tape and tin foil are then removed, the joint inspected, and new protective tape wrapped on, using two pieces, starting at opposite ends and finally ending each beyond the center.

Making a Turk’s-head.—The cable is trimmed square and a wrapping of four or five turns of marline is made about 15 inches from the end. The collar, flat side first, is slipped on until it rests on the marline; the iron wires are bent back regularly over the collar. The jute wrapping is unwound to the collar and trimmed, and all the iron wires are cut with the pliers, removing all but 4 inches and 6 inches from alternate strands; the iron wires are bent separately to fit the collar closely (making two right angles with the pliers), and the ends arranged smoothly along the cable; the end of a piece of marline is engaged under one of the wires near the collar and wrapped regularly and closely around the cable, and the free end of marline secured with two half hitches. About 15 feet of marline are required for single conductor cable; 24 feet for multiple cable.

Testing fuses.—The following apparatus is used for testing in [Pg 36] the loading room: A double-pole double-throw switch, a 150-volt voltmeter, and sufficient dry cells to give a full throw when using the lower scale of the voltmeter. The apparatus is connected up on the testing table so as to make resistance measurements by the voltmeter method. To test fuses, leads are carried from the switch to an iron or other suitable receptacle outside of the building and the fuse leads joined thereto. A full deflection should be obtained when the circuit is closed through the fuses.

Preparing a compound plug for service.—The transformer to be used is first tested for a good circuit between the red wires, a poor circuit between the ends of the black wire, a good circuit between the black or primary lead and the reactance terminal, no circuit between the red and black wires, and no circuit between any wire and the case. The resistance of the circuits is determined by the voltmeter method. The upper end of the black wire (see fig. 8) is prepared for use by baring the wire for about one-half inch and securing it to the binding post in the neck of the transformer. The ball seat is screwed home. The spring plate, distance ring, and ball are placed in the circuit-closer cap, which is held inverted and the transformer screwed into it, the threads being coated with ruberine.

(a) Old model, brass fuse can.—Starting with the compound plug dismantled.

A piece of loading wire is cut about 3 feet long and the ends bared. One end is joined by a telegraph joint to the primary terminal of the transformer and the joint is taped. This wire and the two secondary wires are drawn through the fuse can, which is screwed on the transformer, the threads of the latter having first been coated with ruberine.

Two mine service fuses, which have been tested for continuity of circuit, are connected in multiple across the secondary (red) terminals and the joints taped.

The can is held vertically and the explosive, if trotol, poured in up to the screw threads for the fuse can cap; if dynamite, inclosed in a cloth bag and placed in the can. The fuses are embedded in the explosive. [Pg 37]

The loading wire is drawn through a lead washer and the fuse can cap; the latter, its threads having been coated with ruberine, is screwed into place.

A rubber packing is pushed over the loading wire into the stuffing box in the fuse can cap, a brass gland is threaded down so that it is close against the rubber packing, and the follower is screwed home with moderate pressure. The lower tube is screwed into place, compressing a lead washer between it and the fuse can cap. The threads of the follower and lower tube are coated with ruberine.

The loading wire is drawn through a lead washer and the hole in the plug proper, and the latter screwed hard against the lower tube.

A rubber packing and a brass gland are placed upon the loading wire and forced into their seat in the plug proper by means of the follower, the threads of which have been coated with ruberine.

(b) Rubber fuse can.—Starting with the compound plug dismantled.

Two mine service fuses, which have been tested for continuity of circuit, are cut with 9-inch leads, wires bared for about 1 inch and connected in multiple. A piece of loading wire is cut about 3 feet long and the ends bared for telegraph joints. It is threaded through a hole in a cake of dry guncotton. The two fuses are inserted by pushing each separately into the same hole and the loading wire drawn up until it is the same length above the cake as the fuse leads.

Three other primer cakes are threaded on the wire; two above the fuses, and one below. This arrangement will leave the fuses in the third cake. The cakes are held in one hand with the fuse leads upright, and the fuse can slipped over the cakes, being careful to thread the fuse leads and loading wire through the opening.

The screw threads of the fuse can cap are covered with ruberine and it is screwed firmly into place onto the fuse can. The stuffing box of the cap is assembled.

The plug proper is held upright in a vise. The fuse can, the threads of [Pg 38] the cap having been coated with ruberine, is screwed home and secured by its set-screw. The loading wire must be pulled through the opening in the plug proper with extreme care. It must not be injured in placing the fuse can in position and in screwing it home. The transformer leads are cut about 6 inches long, and the ends bared for 1 inch. The brass collar is screwed on the transformer; a little ruberine on the screw threads facilitates the operation. The connecting collar is slipped over the fuse leads and loading wire and allowed to rest on the fuse can. The transformer is supported by allowing two of the connecting bolts to slip into the holes in the collar; telegraph joints or brass jointers may be used between the secondary leads and the fuses and between the primary lead and the loading wire. The joints are wound with rubber tape, care being taken that there are no sharp ends to cut through the tape.

The transformer is raised vertically above the fuse can until the lead wires are extended. It is lowered and at the same time the leads are coiled in the base of the transformer. As the transformer and collar approach their position on the connecting bolts, the connecting collar is screwed on the transformer, the threads of the transformer having been covered with ruberine. The connecting collar will take care of the remainder of the leads and joints. The set-screw in the connecting collar is screwed home; the brass collar is placed on the connecting bolts and secured in position by the nuts and cotter pins.

The lips of the fuse can and connecting collar are covered with a thin covering of rubber cement. A piece of rubber tape is cut about 18 inches long and laid around this opening without stretching. A piece of protective tape is cut about 18 inches long and laid over the rubber tape with considerable stress. This forces the soft tape over the lips on the connecting collar and the fuse can and makes a tight but flexible joint. The stuffing box in the plug proper is prepared as under (a).

Great care must be taken not to injure the insulation of the loading wire in tightening up the follower in the stuffing box of the fuse can or of the plug proper. [Pg 39]

(c) Trotol fuse can.—Starting with the compound plug dismantled.

Two mine service fuses, which have been tested for continuity of circuit, are cut with 12-inch leads, the wires bared for 1 inch and connected in multiple. A piece of loading wire is cut about 3 feet long and the ends bared for telegraph joints. The loading wire is threaded through the fuse can and cap. The threads of the fuse can are covered with ruberine. The can is screwed into the cap. The threads of the connecting collar are coated with ruberine and the collar is screwed down entirely. The loading wire should project about 4 inches above the connecting collar. The stuffing box of the cap is prepared. The plug proper is held upright in a vise. The fuse can cap, its threads having been coated with ruberine, is screwed firmly into the plug proper by means of a spanner wrench. The loading wire must be pulled through the opening in the plug proper with extreme care. It must not be injured in placing the fuse can in position and screwing it home.

The fuses are inserted in the fuse can, which is filled with trotol to the top of the connecting collar. The transformer leads are cut 4 inches long and the ends bared for 1 inch. The threads of the brass collar are covered with ruberine. It is screwed on the transformer. The latter is raised vertically above the fuse can and lowered on the connecting bolts.

Telegraph joints are made between the secondary leads and the fuses and the primary lead and the loading wire. The joints are wound with rubber tape, care being taken that no sharp ends cut through the tape. The leads and joints are coiled in the base of the transformer. The connecting collar, its threads having been covered with ruberine, is screwed upon the transformer against the brass collar. The bolt-securing nuts and cotter pins are placed in position. The stuffing box in the plug proper is assembled as under (a).

The actual resistance of the assembled plug in the vertical and the horizontal positions is determined by testing with a voltmeter.

[Pg 40]

In service, after the loaded plug tests out satisfactorily, all set screws are set up.

When compound plugs are prepared for drill or for instruction purposes the use of ruberine or other waterproofing material on the screw threads is omitted; care must be taken that the transformer leads are not needlessly shortened.

Loading a mine.—The mine case is carried from the storeroom to the loading room and placed on a loading skid or other receptacle with the loading hole up. The plug is removed and the screw threads are thoroughly cleaned. The explosive detail brings in a box of explosive from the explosive house and inserts a loading funnel into the loading hole. The charge for a 32-inch mine case is 100 pounds of explosive. For the larger cases, the charge should be the maximum that the conditions warrant; it is specified at present as 200 pounds, though larger charges are desirable if enough explosive can be obtained and the excess buoyancy of the case will warrant the use of more than 200 pounds. The cartridges of dynamite, the trotol, or the blocks of guncotton are inserted by hand and so placed in the mine case that there will be ample room for inserting the compound plug. Only one box of explosive for each mine being loaded is brought into the loading room at one time. After the proper amount of explosive has been placed in the mine case the screw threads are thoroughly cleaned with button brushes and then coated with ruberine or other material to prevent access of water. The compound plug, with its screw threads similarly coated, is screwed home with the socket wrench, a lead washer being used between the plug and mine case. A bar put through holes in the sides of the skids and through the maneuvering ring will prevent the case from falling over and from turning while the compound plug is being screwed home.

In order to insure setting the compound plug tight, it is advisable to tap the end of the lever of the socket wrench a few times with a large mallet or a large wooden bar. The mine cap is bolted on and the mine put in a tank for test. If time admits, it may remain in the water 24 [Pg 41] hours. It should show practically the same resistance as the compound plug. If this test be made, the loading wire must be long enough for this purpose.

Upon completion of this test the mine is taken from the tank, the loading wire pushed inside the cap to avoid injury in handling, and the loaded mine taken to the planting wharf.

The precautions to be observed in handling explosives and loading mines are given in Appendix 1.

[Pg 42]

(Note.—The operations in Chapters IV and V are described in what is thought to be the logical order, but circumstances may alter their sequence, and, in fact, several of the steps may be carried on simultaneously.)

For the work on the water there will be needed five boats, viz., a mine planter or suitably fitted-up heavy tug, a small tug or heavy launch called the distribution box boat, and three launches or yawls. The capacity of the planter is such that a group of 19 mines can be handled at one time.

The instructions to be observed by the master of a mine planter in marking out a mine field and in planting mines are to be found in Appendix No. 6.

Determining location for distribution box.—From an examination of the chart, or of the approved scheme for mining, the locations of the lines and groups of mines are determined. A distribution box is to be placed about 350 feet in rear of the center of each group of mines. The locations for the distribution boxes are marked on the plotting board and their azimuths from each of the ends of the horizontal base or their azimuth and range from the vertical base station are determined.

Marking location of distribution box.—An anchor with buoy attached is placed upon the deck of a small tug and carried out to one of the selected spots. By a system of signals the boat is directed to the location determined and there the anchor is thrown overboard. The locations for the other distribution boxes are marked in a like manner.

Laying multiple cable.—The cable-reel is placed upon the [Pg 43] forward deck of the planter and raised on the jacks. The planter then proceeds as near the mining casemate as the depth of water permits, and one end of the cable is passed ashore, either by a launch, by yawls, or by any other suitable method. In case the planter can not approach nearer the shore than 100 yards it will be necessary to coil more than enough cable to reach the shore in a figure of eight in a yawl, which is then towed toward the desired point on shore, the men aboard the yawl paying out the cable as it proceeds. This end is drawn in through the conduit or gallery to the casemate or terminal hut. It may be secured by taking a telegraph hitch around it with a chain and spiking the chain to some heavy timbers or fastening it to some holdfast. When cable ends have already been laid they will be picked up and joined to the multiple cable for the groups.

The shore end having been secured, the planter moves out to the position of the distribution box, unreeling the cable as it goes. If the water be very deep, a friction brake must be extemporized to prevent the reel from overrunning. (While the planter is laying the cable, the casemate party tags and attaches the shore end as explained later.) To prevent kinks as far as possible cable should be laid with as much tension as practicable.

If the cable is not long enough, a second one must be joined to it. This is preferably done by passing the ends to a small boat. The junction is made, either using a junction box with Turk’s-heads and taped joints, or opening back the armor for about 5 feet from the ends, making taped joints, protecting them with tape, and then rewrapping the armor and seizing the ends with wire. Care must be taken to join the proper conductors of the two ends.

In the meantime the distribution box boat with a detachment of one noncommissioned officer and five men takes the distribution box and moves out to the spot marked by the buoy. It picks up the buoy and makes fast to the anchor line.

The planter continues laying the multiple cable until it reaches the distribution box boat. The multiple cable is then cut and the end passed to the distribution box boat, usually by a heaving line. The [Pg 44] cable is lashed to the boat; a Turk’s-head is worked upon the end and then secured in the distribution box. As a precautionary measure for the recovery of the distribution box, should it be lost overboard during mine planting, it is well to have the multiple cable buoyed about 100 yards in rear of the distribution box.

In case it may be desired not to use the distribution box at once, the separate conductors of the multiple cable should be tagged, tested, and insulated. The cable should be buoyed and dropped overboard to be recovered subsequently.

Identifying, tagging, and testing the conductors of the multiple cable.—Tagging.—In the casemate the conductors are separated, carefully identified, tagged, and attached to the corresponding terminal of the terminal bar on the operating board. The mine switch for No. 19 is opened and the telephone terminal attached to its stud so as to use No. 19 for communicating with the distribution box boat. The ends in the distribution box boat are separated, one terminal of a boat telephone is attached to No. 19, and the other earthed either by attaching to the cable armor or to an earth plate hanging overboard in the water. Communication is thus established with the operator in the casemate. Nos. 1, 13, and 19 are picked out easily; the remaining ones are tagged in contraclockwise direction.

Verifying the tagging.—The casemate is then notified that the boat party is ready to check the tagging. This is done as follows: The power switches on the operating board are all closed, except 19, and direct current put on the cable by closing switch No. 3 up. The casemate operator then directs the boat party to earth in regular succession the various conductors. This is done most quickly by touching the conductor to the cable armor. The corresponding automatic switch on the operating board should drop. Any errors in tagging detected by this test should be corrected at once. This test also checks the continuity of circuit of each conductor.

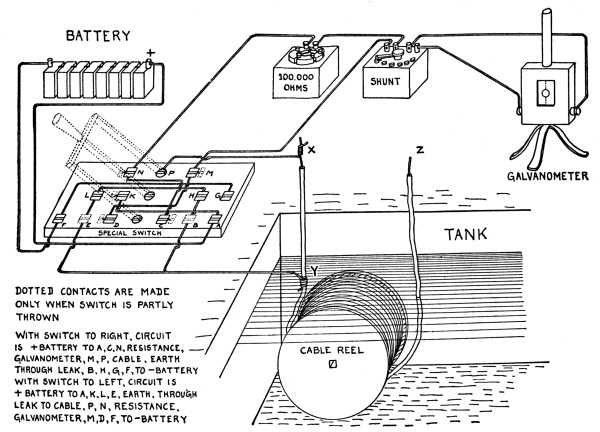

Insulation test.—The operator then directs the boat party to prepare the cable end for insulation test. This is done by separating the conductors, holding them in the air, and drying them if necessary. [Pg 45]

When prepared, word is sent to the casemate operator, who tests as follows: He closes switch No. 7 up. This throws D. C. power on the mil-ammeter plug of the operating board and introduces in the circuit the mil-ammeter and its protective lamp. The green lamp is then unscrewed and the mil-ammeter plug used on the D. C. jaw.

If there be no leak in the multiple cable, since the ends at the distribution box boat are held in the air, there will be no appreciable reading of the mil-ammeter.

If there be a leak, this fact will be revealed by a reading on the mil-ammeter. To discover the particular conductor or conductors on which this leak exists, each power switch is opened in succession and the mil-ammeter plug inserted on the jaw of the power switch.

No. 19 is now tested in the same way by first shifting both telephones to No. 1, the boat end being held in the air. The operator reports the result of the test.

Upon completion of these tests the power is turned off. Post power should not be used for testing, because the negative side of the post power may be grounded.

Marking out the mine field.—In using automatic anchors it is not necessary to mark the mine field; but in using mushroom anchors it is generally done. The material required consists of 1 measuring line with reel and frame, 5 anchors, 5 keg buoys, and 5 raising ropes.

A buoyed anchor is dropped about 350 feet in front of the distribution box buoy. This marks the position of mine No. 10 and of the center of the group.

This marking buoy is picked up by a launch which makes fast to the anchor rope. The planter now passes to the launch one end of a measuring line, which has marks at 280, 300, 350, 580, and 600 feet. These marks may be made by painting 3 feet of the measuring line some distinctive color at the designated points. The planter moves out slowly along the line to be occupied by the mines, unreeling the measuring line as it goes, and drops buoys at the 300 and 600 foot marks. It then returns and does the same for the other side of the [Pg 46] line. These five buoys mark the line to be occupied by the mines, indicate the positions of mines Nos. 4, 7, 10, 13, and 16, and in addition cut up the distance into 300-foot lengths, which enable the planter to plant mines at a close approximation to 100 feet apart.

Taking soundings on line of mines.—When automatic anchors are used, such information as may be required about depth of water may usually be obtained from charts. This may not be sufficiently accurate for planting with ordinary anchors. In the latter case soundings must be taken at the spots where the mines are to be planted.

These soundings are made from the launches. The launches take a measuring line marked at every 100 feet, stretch it between the planted buoys, and take the soundings at every 100-foot point. The soundings are recorded in a blank book showing the number of the corresponding mine and state of the tide. It may be found more satisfactory to hold one end of the measuring line at the buoy and circle across the line of mines with the launch, getting the sounding at the point of crossing.